Copyright © 2025 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map

Box drawing type facial tissue machine use tissue jumbo roll to Process folded into "V" type paper processing equipment. The machine adopts the vacuum adsorption principle and auxiliary manipulator folding.

Automatic transferring facial tissue paper folding machine XY-GU-20A

Design Speed:100m/min

Stable Speed:70-80m/min, or Max. number of long stacks: 6-10 long stacks/min(meet only one of them)

Max.Width of jumbo roll:1400mm

Daily Capacity:about 7.5T/22 hours (jumbo roll:three layers and 15g/m²)

Jumbo roll paper:2-3 ply

Raw Material of jumbo roll:straw paper,wood pulp paper,sugarcane pulp paper,bamboo pulp paper and so on

Jumbo Roll Specification:2 ply:14-18g/m²/ply;3 ply: 13-15g/m²/ply

Feature and Functions:

The paper-breaking knife roller adopts the structure of the spiral knife roller, which effectively solves the stability of the paper-breaking and the service life of the blade.

The structure of the paper-breaking knife roller adopts the structure of the spiral knife roller from the original straight knife to the full-cutting type, and the spiral knife roller is the point-cutting type, which solves the instability of the paper break and the short life of the blade caused by the original straight knife structure.

Configuration:

A production line includes the following parts:

No. | Description | QTY | unit |

1 | unwind stand | 2 | set |

2 | folding device | 1 | set |

1.Air source system: the air source is prepared by the buyer, and the air source access point is connected to a point which is 1-2 meters away from the gas point and equipped with a shut-off valve, which is according to the seller's requirements. The required pressure of the air source: 5-6kg/cm².

2.Power system: the power supply is prepared by the buyer, and the power supply is connected to the electrical control cabinet of the contract machine according to the seller's requirements.

3. Vacuum system: The piping required for vacuum connection is prepared by the buyer.

Technical Parameters:

1.1 Unwind stand(shaft type and 2 jumbo roll stands/set)

No. | Description | Technical parameters |

1 | Max. width of jumbo roll(mm) | 1400 |

2 | Jumbo roll diameter(mm) | <=¢1500 |

3 | Unwinding speed(m/min) | <130 |

4 | Inner diameter of jumbo roll | ¢76.3mm |

5 | Machine structure | Wall type and frame structure |

6 | Weight of jumbo roll(T) | Max.0.8 |

7 | Uncoiling system | Sheet base belt paper feeding belt |

8 | Alignment of jumbo roll | Manual adjustment |

9 | Unwind Mode | Clockwise |

10 | Paper threading method | Manual |

11 | Detection of paper break | With a paper break detection system, the whole machine will stop when a paper break occurs, reducing the waste of raw paper |

12 | Power | 1.5KW |

13 | Minimum air pressure requirement | 0.6Mpa |

14 | Gas consumption | 1000 liters/shift |

15 | Transfer mode of jumbo roll stands | Independent motor to control |

Transmission | ||

16 | Conveyor belt | Flat belt drive |

17 | Jumbo roll adjustment | Screw drive |

18 | Protection | The main transmission components are protected by a protective cover |

1.2 This unit includes:

Description | QTY |

Conveyor system | 1 set/group(on the rear shelf) |

Jumbo roll centering system | 1 set/group(on the rear shelf) |

Jumbo roll paper threading system | 1 set/group(on the rear shelf) |

Transmission system | 1 set/group(on the rear shelf) |

Jumbo roll fixed base | 2 sets/group(on the rear shelf) |

Jumbo roll shaft | 1 set/group(on the rear shelf) |

Jumbo roll fixation and exit system | 2 sets/group(on the rear shelf) |

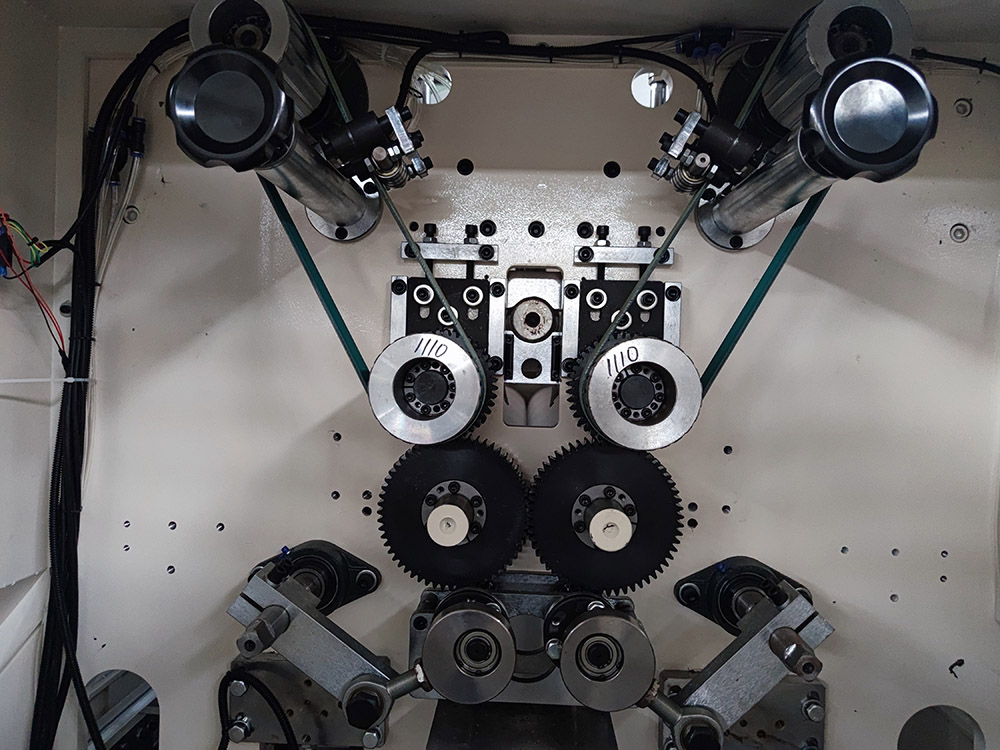

2.1.1 Mainframe Folding Device (1 group/set)

No. | Description | Technical parameters |

1 | Design speed | 100 m/min |

2 | Stable Speed | 70-80m/min, or Max. number of long stacks: 6-10 long stacks/min(meet only one of them ) |

3 | Unfold size of finished product (mm) | 180(+1,-3)* finished product width |

4 | Folded size of finished product(mm) | 90(+3,-1)* finished product width |

5 | Height of finished product(mm) | 50mm-135mm(Folding height,not the packing height) |

6 | Machine structure | Wallboard structure |

7 | Counting method | High resolution encoder operation(100% accurate) |

8 | Folding method | Vacuum adsorption folding |

9 | Folding style | V-shaped staggered folding |

10 | Processing method of folding roller ·

| After quenching and tempering, and using high-precision deep hole processing to ensure the rigidity and strength of each roller, and all are processed by CNC machining center. G3.2 level dynamic balance ensures the accuracy of the folding roller during high-speed folding process. |

11 | Folding roller of break paper | There are 2 paper breaking folding rolls, and there are 3 to 4 paper breaking bottom knives distributed on the roll averagely (the number will change according to the specification), so as to ensure that the length of each paper breaking is 180 (+ 1, - 3) mm, and there are regular vacuum adsorption holes beside each bottom knife on the roll surface, which are used to adsorb the cut base paper attached to the roll surface |

12 | There are 3-4 inserting knives and 3-4 folding V-slots on the roll (the number will change according to the specification), which ensures that the size of the base paper after folding is 90mm (+ 3, - 1), and there are regular vacuum adsorption holes beside the inserting knives and folding V-slots on the roll surface, which are used to adsorb the cut base paper attached to the roll surface | |

13 | The down blades | All of them are processed with imported materials, and the structure of down blades and suction hole ensures that the paper will not be turned over when cutting at high speed, which makes the finished products more neat. |

14 | The up blades | All of them are processed with imported materials, and the design of blades adopted to ensure the knives’ durability |

15 | Method of cutting paper | Overall lifting. There is a spiral blade at the front and back. Spiral paper breaking structure makes paper breaking stable and blades durable. |

16 | Paper threading method | Manual |

17 | Vacuum duct structure | Vacuum duct piping and construction shall be responsible by the buyer |

18 | Machine inching function | The machine can select the inching function |

19 | Main motor power (kW) | 4KW |

20 | Vacuum pump power(kW) | 22 |

21 | Power(V Hz) | 380v 50Hz 3Phase |

22 | Voltage (V) | 24 |

23 | Compressed air pressure(MPa) | ≥0.6 |

23 | Gas consumption | 1000 liters/shift |

2.1.2 This unit includes:

Description | QTY | Description | QTY |

Paper feed roller | 2 rolls (on the main machine) | Spiral knife roll | 2sets(on the main machine) |

Paper folding roller | 2sets(on the main machine) | The bottom roller of cutting paper | 2sets(on the main machine) |

Suction assy | (on the main machine) | Curved roller | |

Shifting fork assy | 2sets(on the main machine) | Mechanical transmission system | 2sets(on the main machine) |

Shifting fork control syustem | 2sets(on the main machine) | Vacuum pump | 1set |

2sets(equipped with the main machine) | |||

Baffle system | 2sets(on the main machine) | Electricity box | 1set(on the main machine) |

protection cover | 1set(on the main machine) | Detection system of paper breaking | 1set(on the main machine) |

Control system of paper breaking | 2sets(on the main machine) | Touch screen | 1set(on the main machine) |

2.2.1 Edge Embossing system(full embossing can be customized) 1set/group

No. | Description | Technical parameters |

1 | Edge embossing function | The machine is equipped with two sets of edge embossing devices, the distance between the edge embossing lines is adjustable, and the minimum distance is 35mm

|

2 | Number of edge embossing wheels | Can be customized(standard ?sets) |

3 | Implementation of edge embossing | Each group of embossing can be adjusted separately by using airbag, and the embossing wheel is driven passively |

4 | The bottom rolls of edge embossing | There is embossing roller at the front and one at the back |

5 | Edge embossing wheels | The bearing is reformed and the surface of the bearing is treated with electric pattern; The shape, distance of embossing lines and effect of edge embossing shall be specified by the buyer and confirmed by both parties. The edge embossing wheels can be used for more than 6 months. |

6 | The bottom rolls of edge embossing | Using bearing steel heat treatment, ensure HRC60 degree above, and special surface treatment, guarantee to use for more than one year |

7 | Lubrication mode | There is an independent lubrication device for each group of edge embossing wheel |

8 | Switch of edge embossing system | By operating touch screen to choose facial tissue with embossing or without embossing |

9 | Compressed air pressure (MPA) | ≥0.6 |

10 | Gas consumption | 500 L/ shift |

2.2.2 This unit includes:

Description | QTY | Description | QTY |

Bottom rollers of edge embossing | 2sets(on the main machine) | Embossing system | (on the main machine) |

Wheels of edge embossing | 8 set |

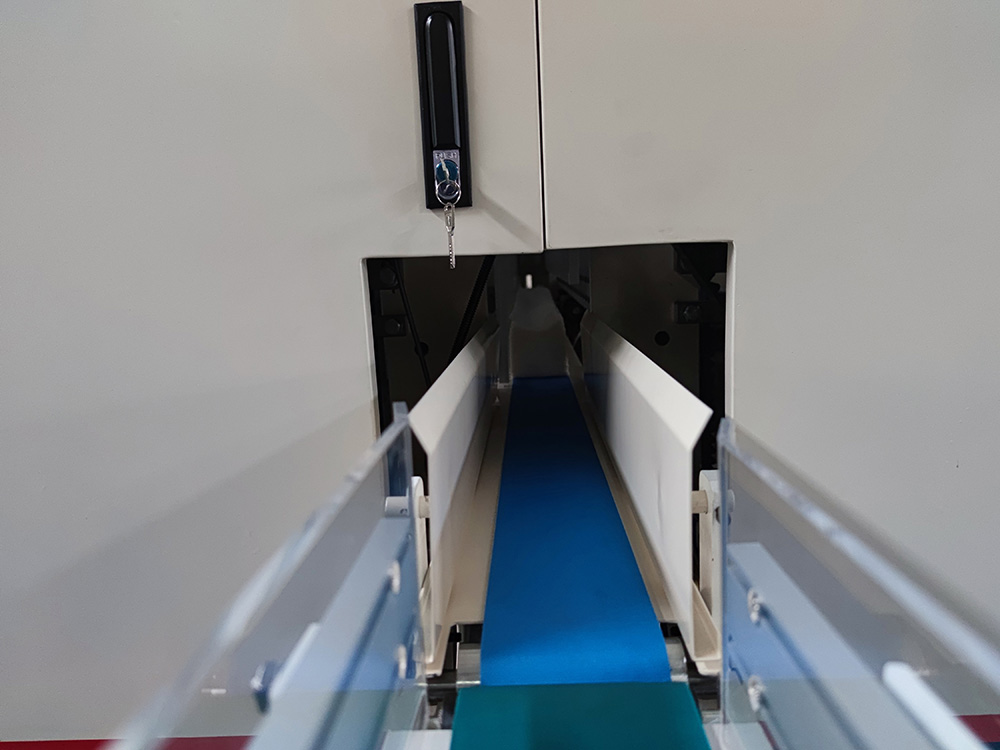

3.1 The automatic transfer system 1set/group

No. | Description | Technical parameters |

1 | Transfer system | 4 servo control devices can realize automatic transfer |

2 | Transfer structure | Wallboard structure |

3 | Sliding device for transfer | All the sliding devices adopt imported linear bearing, and adopt double shaft structure to ensure the stability of each part of transferring system |

4 | Main Transferring workpiece | All of them are made of aluminum alloy and processed by CNC machining center, which ensures the accuracy of transferring |

5 | Paper out baffle | All of them are processed of imported aluminum alloy, to ensure that the out paper will not affect the transferring effect |

6 | Pneumatic parts | AIRTAC pneumatic components is used to ensure the accuracy of transferring |

7 | Tracking amounts of sheet | High precision encoder is adopted |

8 | Adjustment of amounts of sheet | Set on PLC screen and the amounts of sheets can be adjusted 100% accurately (with even number as the setting reference) |

9 | Amount range of sheets | 2 plys: 100-200 sheets,three plys 60-150sheets |

10 | Speed | Max. 10 times/min |

11 | Control mode | When the machine is shut down normally, it can only be shut down after the transferring work is completed |

13 | Paper support parts | Stainless steel is used to ensure the strength and rigidity of semi-finished product at high speed |

14 | Power(kW) | 3+3+0.75+1.8=8.5 |

15 | Compressed air pressure (MPA) | ≥0.6 |

16 | Gas consumption | 1000 L/ shift |

17 | Control voltage(V) | 24 |

3.2 This unit includes:

Description | QTY | Description | QTY |

Paper handling and supporting servo | 2sets(on the main machine) | Holding system | 1 set/each (on the main machine) |

Insertion servo | 2sets(on the main machine) | Paper insertion | 2sets (on the main machine) |

Productivity Calculation(Beow is an example)

Jumbo roll paper specificaiton:15gsm, 6 ply

Jumbo roll width: 1400mm

Coefficient of efficiency: 65%

Production time: 22 hours

Production speed:70m/min

No. Of machines:1set

Note:above productivity calculation is only for reference.

The specific production capacity is related to the gram weight, characteristics of jumbo roll paper, product specifications and the specific situation of each company.

Jumbo roll standard

Embossing

Folding device

Output device

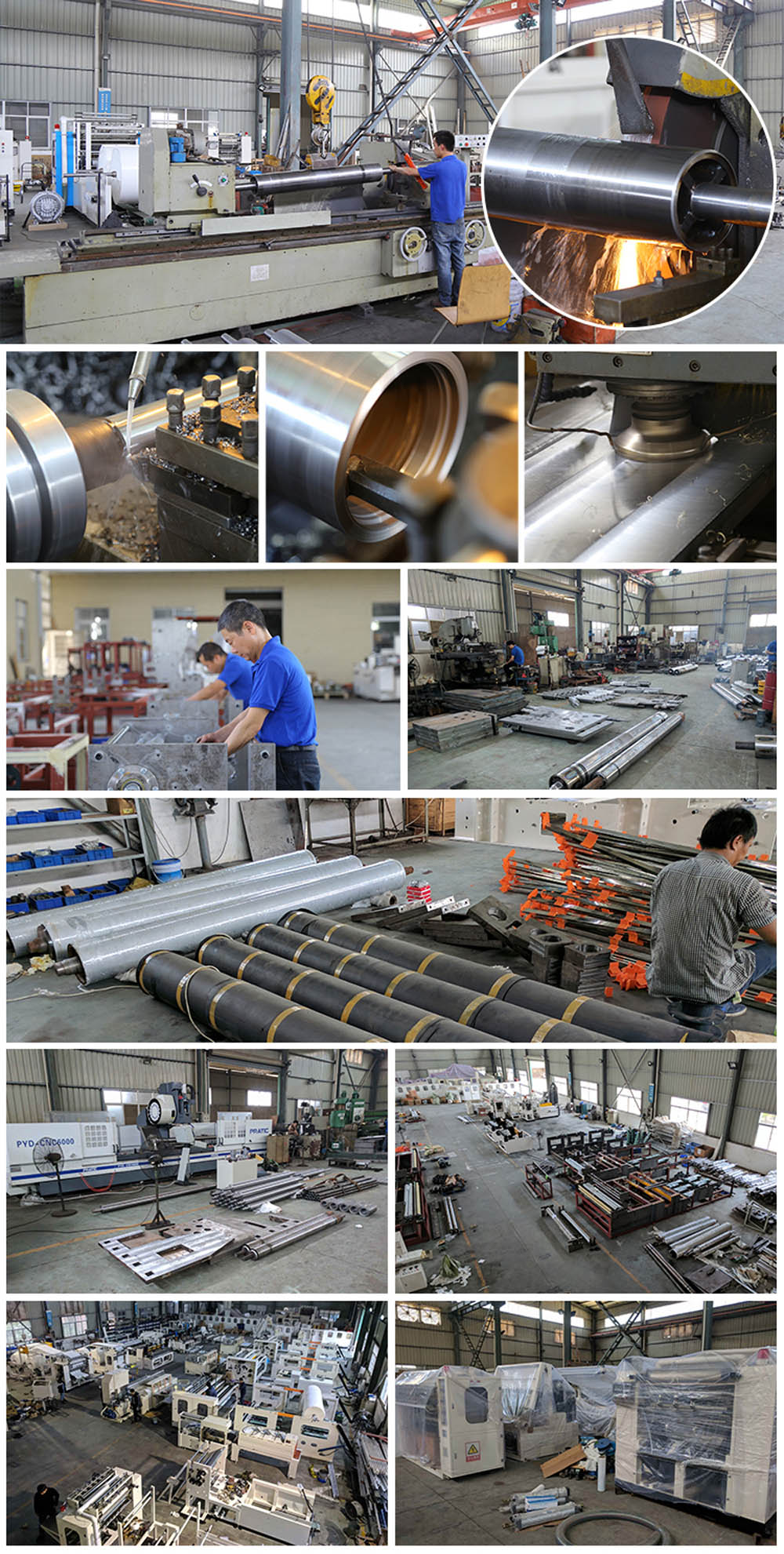

Our service

Packing

Workshop

Professional supplier of:

1) Toilet Paper Machine (1.2m--2.8m width of parent roll, Customize Service)

2) Roll Kitchen Paper Towel Machine (1.2m--2.8m width of parent roll, Customize Service)

3) Facial Tissue Machine (2-8 output lanes)

4 )Napkin Paper machine(L-fold, 1/4-fold, 1/6-fold, 1/8-fold and other multi-fold type)

5) Hand Towel Paper Machine(C-fold, V-fold and N/Z fold type)

6) Pocket Tissue Machine(mini and standard size)

7) All kinds of Tissue Paper Cutting and Packing Machine

8) Another Household Paper Equipments and Production Line.

Welcome to contact us to get more details !

We can design the machine according to your request.

By continuing to use the site you agree to our privacy policy.