Copyright © 2025 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map

XY-TQ-B Automatic toilet paper and kitchen towel paper machine

1. Power Connection: Three Phase,four lanes road, AC380V, 62A.

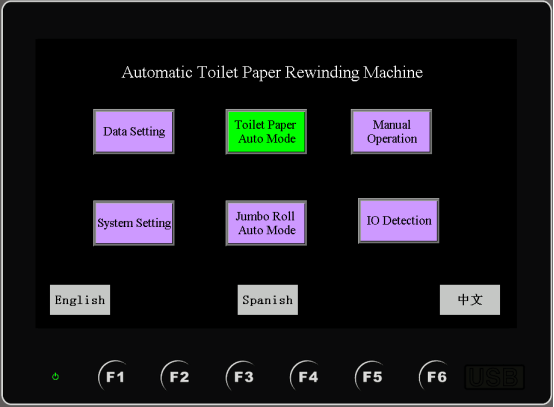

2.After power on, Human Interface displays as follows:(You can choose English or Chinese version)

1、 The parameter setting refers to the coordinated adjustment of all machinery, cylinders and solenoid valves. Achieve the fastest and best operating state setting;

2、System settings refer to the synchronous settings of rewinding, embossing, punching and material running speed. This settings are generally factory parameters and are in the best state. Operators can not change them at will. 3. Sealing Heating Time: Transverse heating wire heated time, the data can be set between0.2-0.5 seconds, if the time is short, can seal well, if too long, the bag will be burned, or the heating wire will be fused.

3、The automatic mode of toilet paper rewinding refers to the setting of rewinding knots, the fine-tuning of material speed and the opening of each cylinder when entering the automatic operation screen, which can check the given speed and output, etc.

4、Manual operation refers to the entry screen can run the cylinder alone, cutting tool operation can also set the main engine's point speed. This page is usually used for debugging.

5、The automatic mode of slitting and rewinding small tray paper is similar to the automatic mode of toilet paper rewinding, but there are not so many mechanical devices.

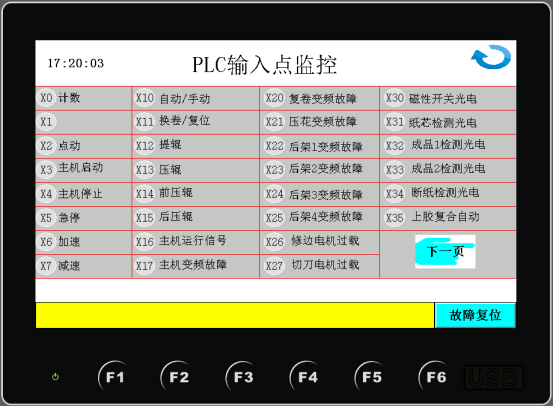

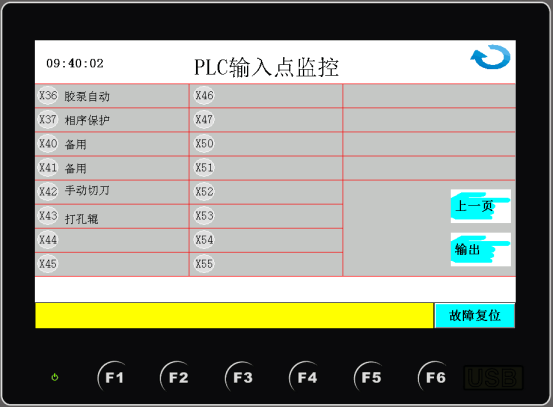

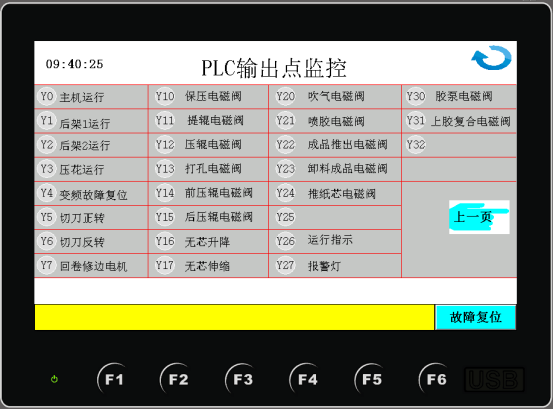

6、IO monitoring refers to the Plc input and output points monitoring/displaying the operation status of each input and output point.

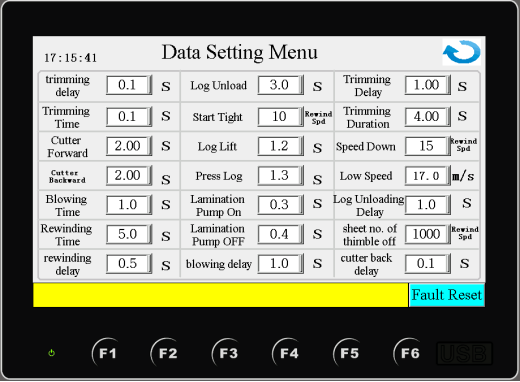

Operation Menu: The button can be set according to the parameters of the man-machine terminal screen to enter the operation as follows.

1. Delayed trimming refers to the time when the finished product is pushed to the rewinding device to wait for trimming after rewinding is completed.

2. Trimming time refers to the time when the finished product is pushed to the trimming of the rewinding device

3. The feed/withdraw time sets the time when the cutter moves forward and returns to its original position. This setting is set when the cutting knife is not in place or when the cutting knife is not in place or when the forward and backward time is too long.

4. The setting of delayed blowing and blowing time refers to the setting of the time for delayed blowing to wait for the blowing time, while the blowing time is the time when the paper core is in place and the blowing time is the time for the paper to cover the paper core and blow.

5. Rewinding delay/rewinding time settings refer to the time waiting for rewinding after the cutter has been cut. Rewinding time is the time when the finished product is rolled up after the cutter has been finished.

6.The setting of unloading time refers to the length of unloading time.

7. Firstly, the number of tightening knots is the number of knots that start rewinding at low speed, and the number of low running knots has reached the fast rewinding mode.

8. The time setting of lifting and pressing rolls refers to the waiting time of lifting and pressing rolls, i.e. when to lift the rolls.

9. The setting of the opening/closing time of rubber pump refers to the time from the beginning of operation to the closing of the rubber pump and the time from the start to the closing of the rubber pump.

10. The setting of delayed spraying/spraying time refers to the setting of spraying time when the cutter runs to the edge of the paper.

11. Low-speed knot setting refers to the number of knots running at low speed at the end of rewinding.

12. Low speed setting refers to the speed adjustment of low speed operation at the end of rewinding.

13. The setting of delayed unloading time refers to how long the unloading time will be adjusted after the finished product is ready.

14. The setting of thimble withdrawal number refers to the withdrawal of the thimble on both sides after several sections of rewinding.

15. The setting of delayed return time refers to the residence time when the cutter goes to the other end.

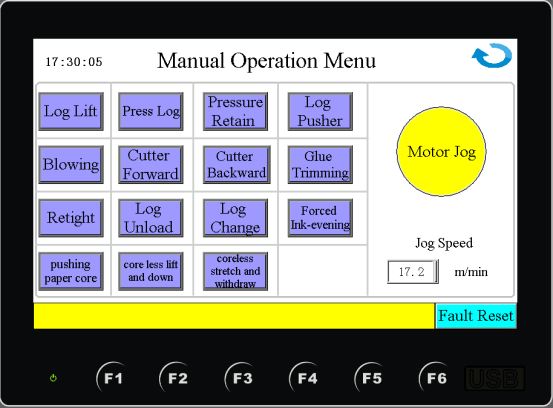

The manual mode button on the right side of the man-machine terminal screen can be used to enter the manual operation as follows.This screen is the manual debugging screen of each cylinder and motor.

Note: Pointing speed is generally set between (15 - 20). Press the main engine button to point rewinding and pointing operation.

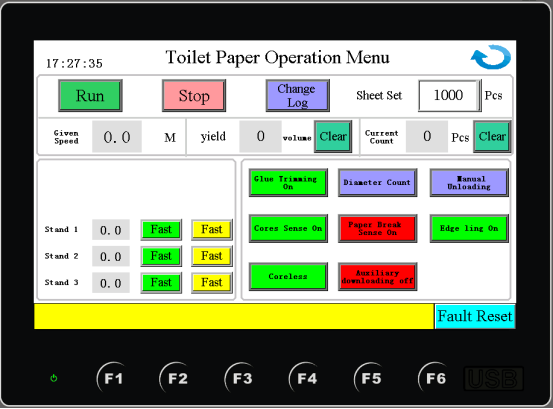

According to the toilet paper rewinding operation screen button in the middle of the man-machine terminal screen, the automatic operation can be entered as follows

1. This page clicks the automatic button to realize automatic operation, press stop rewinding and stop operation.

2. Pressing the button when rewinding stops can realize the function of rewinding during debugging or running.

3. The given speed is the speed given by the acceleration and deceleration switch.

4. Setting the number of sections and the current number of sections is the length of the rewinding and displaying the number of sections now, which can realize the zero-clearing operation.

5. Complex, embossing and back rack 1, 2 and 3 on the left can view the current running speed and run meters in real time, and can be fine-tuned according to +, -。

6. The buttons on the left can realize the functions of opening or closing the components, such as spraying off, knot counting mode, manual unloading, paper core, paper breaking detection, auxiliary blanking, paperless core and so on. For example, if you have a paper core, you should open the button with a paper core.

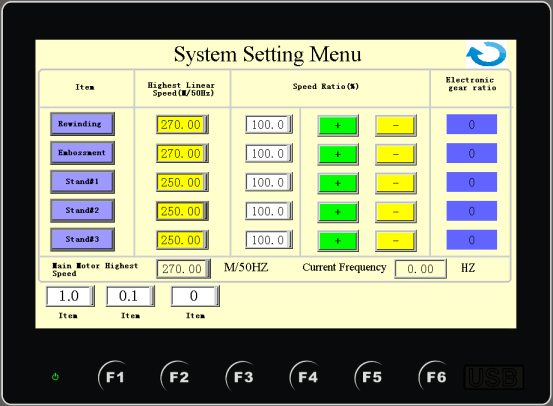

Hidden parameter screen: you can press the system configuration screen button in the middle of the man-machine terminal screen to enter the operation as follows. (If you click the "system configuration" button in the boot screen, you will get the password of input permission, which is 5188. If you input correctly, you can enter the following screen.)

Note: This page is manufacturer's parameter, which requires professional operation.

1. Rewinding, embossing and rear rack 1, 2 and 3 on the left can set the maximum running speed, i.e. the speed out of the highest frequency of the converter. Press the button to open or close the rewinding, embossing and back rack 1, 2 and 3 separately. Set the speed ratio so that all operations can be synchronized. Finally, the electronic gear ratio is displayed.

2. Setting the maximum speed of the host. And the host shows the current running frequency.

3. Delayed finished product is delayed closure of auxiliary cutting time.

4. The number of degumming knots in advance refers to the number of running knots when the compound rubber pump is stopped.

5.Delayed core feeding refers to delayed core feeding.

The IO input and output port of the PLC can be monitored by pressing the IO monitor button in the middle of the man-machine terminal screen as follows.

The automatic mode of slitting and rewinding other small tray paper is debugged according to the automatic mode of toilet paper rewinding.

After work, please shut the power off in time, do daily maintenance, Thanks for choosing our machines!

By continuing to use the site you agree to our privacy policy.