Copyright © 2025 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map

Pocket tissues are part of daily routines. We carry them in handbags, car compartments, and school bags without thinking twice. They're used quickly, but making them is anything but simple. Behind each soft, folded sheet is a fast, coordinated manufacturing line.

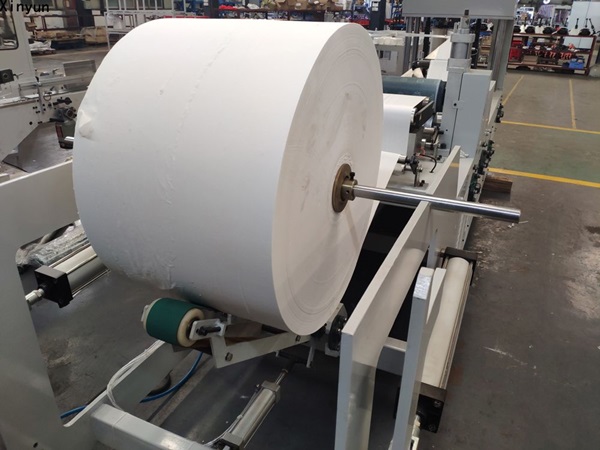

Everything begins with jumbo tissue rolls. These large rolls, often weighing several hundred kilograms, are the raw input material for the entire line. They're typically made from virgin pulp for a soft, clean feel or from recycled pulp to lower production cost. Sometimes, manufacturers blend both to strike a balance between comfort and sustainability.

But quality goes far beyond the type of pulp. Moisture level, ply count, thickness, and tensile strength must all be consistent across the roll. Variations in these properties can result in production issues like tearing during unwinding or uneven folding. Before the roll ever feeds into a machine, operators inspect it—checking width, firmness, and texture to avoid problems later on.

Defects in the initial roll create ripple effects downstream. A single bad roll can cause dozens of faulty packs. That's why this early step gets special attention. If it passes inspection, only then does production move forward.

Once approved, the jumbo roll is placed on the unwind station. This step seems simple, but it's surprisingly technical. Consistent tension must be maintained throughout the feed. Too tight, and the paper tears; too loose, and it wrinkles or jams.

Sensors and motors regulate this process in real time. The line adjusts feed pressure automatically to match changes in roll weight or machine speed. Even tiny shifts in humidity or paper quality can impact tension. That's why constant monitoring is essential.

Some setups include buffer rollers to absorb fluctuations. These mechanical cushions help smooth out any sudden shifts. The goal is to create a clean, even feed into the embossing station.

After unwinding, the paper reaches the embossing unit. This is where the sheet gains its texture and character. Steel rollers press subtle patterns—floral, diamond, or grid—into the surface. These patterns make the tissue feel thicker and softer.

But embossing isn't just about looks. It strengthens the bond between layers by increasing surface friction. This prevents layers from sliding apart when pulled from the pack. The effect must be strong enough to hold but not so deep it weakens the sheet.

Calibrating roller pressure is a delicate balance. Operators check depth with precision gauges. If embossing is uneven, it shows up immediately in folding and stacking later.

This is also the point where optional treatments are added. Some machines spray a light layer of lotion or fragrance. Others stay untreated for customers who prefer chemical-free options.

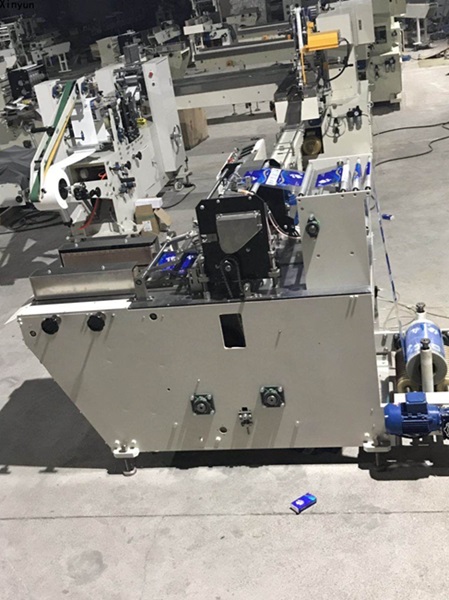

Folding gives the tissue its final shape. Sheets are drawn into folding arms that create V or Z patterns. Each fold must align perfectly with the next, or the stack becomes crooked. That small misalignment can ruin an entire pack.

Vacuum suction, guides, and air jets work together to make folds crisp and consistent. The speed and pressure are calibrated depending on sheet thickness. Heavier paper needs stronger suction. Thinner stock requires a gentler touch.

This step often involves a handkerchief folding machine, a specialized device designed to produce tight, compact stacks ideal for pocket-sized packs. It ensures each fold is clean, uniform, and reliable across high-speed production.

The folded stack must stay compact yet expandable. It has to fit inside small wrappers but unfold smoothly when pulled. That balance between tightness and usability defines product quality.

Some machines allow format switching with the press of a button. Operators choose fold type, sheet count, and stack height from a digital menu. This adaptability supports a wide range of private label requests.

After folding, the long sheet is cut into stack-length sections. The blades—rotary or guillotine—must be sharp and aligned. A dull blade leaves rough edges. Misaligned blades cause angle cuts or missed sections.

Speed synchronization between the folding and cutting units ensures clean, straight results. Sensors check each cut's position. Reject systems remove any pack that doesn't meet the length or edge standards.

Each blade setting is adjusted depending on the tissue's thickness and number of plies. Maintenance here prevents most defects.

Once cut, the tissues move to the packing section. A plastic film is formed around each stack and sealed. This is where the “pocket pack” appearance is created. The film can be plain, printed, or even perforated for easy opening.

Heat sealing is most common. It bonds the film around the tissue without damaging it. Ultrasonic sealing is another method used with thin or specialty films. Either way, the seal must be strong and clean.

Proper sealing protects the tissue from moisture, dust, and damage. Film alignment is checked by cameras. Miswrapped packs are automatically rejected.

With each pack sealed, a printer applies batch numbers, production dates, or barcodes. High-speed inkjet systems do this inline, without stopping the machine.

Once labeled, packs are grouped. Machines stack them into tens, twenties, or larger display units depending on the order. Bundles are sealed in shrink film or boxed. Each step is automated and tracked.

Grouping affects how the product appears in stores. For example, travel-size packs might be bundled with carry handles, while bulk units are boxed for retailers.

Pocket tissues are hygiene products, so cleanliness is essential. Machines use stainless steel parts in contact zones. Covers and air filters keep dust and debris out. Employees follow sanitation procedures and wear gloves, masks, and caps.

The environment is monitored for temperature and humidity. High heat or moisture changes can affect sealing and cutting. Frequent cleaning prevents pulp buildup on rollers and blades.

Production lines are often placed in semi-clean rooms, where airflow and surface contact are controlled. These details prevent contamination and maintain product safety

Throughout the process, hygiene is non-negotiable. Pocket tissues are personal care products, so contamination is unacceptable. Machines use stainless steel parts that resist buildup. Operators clean them daily.

Production rooms often use filtered air systems. This keeps out dust and airborne particles. Workers wear gloves, masks, and sometimes even full gowns depending on policy.

In some plants, cleanroom-like standards apply. Temperature and humidity are controlled tightly. Even the floor coating is chosen for easy disinfection.

Waste tissue and film scraps are collected in sealed bins. They never re-enter the production stream. These efforts protect both product quality and brand reputation.

Every phase includes quality control. Sensors check for tension, thickness, fold height, and sealing alignment. Visual cameras detect logo position and edge straightness. Errors are flagged and rejected instantly.

Automated systems handle most of the checks. But human eyes still play a role. Inspectors take random samples and test them by hand. They feel texture, pull sheets, and measure pack dimensions.

Checklists guide these inspections. Operators log issues and track fixes. If a defect shows up repeatedly, the machine is paused and recalibrated.

These steps catch problems early. A small flaw at the embossing stage might not show up until sealing. That's why inspection continues until the last pack leaves the line.

Consumer needs differ from place to place. Some regions like fragrance, others don't. Some want minimal plastic; others prefer strong wrap. That's why machines must be modular and adaptable.

Changeovers are frequent and fast. One line may switch from 8-sheet to 10-sheet packs several times a day. Digital presets let operators swap formats with minimal delay.

Embossing rollers, film rolls, and folding arms can all be replaced quickly. Recipes for each pack type are stored and recalled from memory. This reduces training time and boosts efficiency.

Flexibility also means lower waste. When formats are easy to change, fewer errors occur during setup. That keeps both costs and scrap rates low.

Factories track:

Packs per minute

Rejection rate

Seal failure rate

Changeover time

Material waste

These numbers help identify problems and opportunities. Reducing the reject rate from 2% to 1% could mean thousands more sellable packs each day. Faster changeovers improve delivery time.

Operators use dashboards to watch these metrics in real time. Machines with smart sensors adjust automatically when settings drift slightly. This keeps everything running smoothly.

What seems like a minor product is actually the result of well-calibrated machinery, synchronized workflows, and attention to hygiene at every stage. Pocket tissues may be small, but producing them at scale takes more than just paper and plastic—it requires precision engineering. For manufacturers aiming to improve efficiency and quality in this category, Xinyun Machinery offers integrated pocket tissue production solutions built for speed, consistency, and long-term performance.

Reach us at [email protected] or visit https://www.xinyun-engine.com/

By continuing to use the site you agree to our privacy policy.