Copyright © 2025 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map

Napkin paper often goes unnoticed—until it fails. Whether it's too rough, too flimsy, or leaves color on your fingers, poor-quality napkins quickly ruin the experience. So, what defines a high-quality napkin paper? The answer lies in both its physical traits and the way it's made.

The tactile impression a napkin leaves is immediate. Good napkin paper must balance softness and structure. It should feel gentle against the skin without being slippery or thin. Customers don't want a napkin that feels like plastic wrap, nor one that scratches like rough cardboard.

A good napkin doesn't just feel soft—it feels correct for its setting. In casual dining, a slightly fibrous surface helps grip fingers and clear oil without sliding. In upscale environments, a smoother texture signals elegance without losing control. The ideal tactile profile adjusts subtly depending on the context, but always lands between comfort and effectiveness. The wrong texture—too slick, too coarse, too fragile—immediately undermines user trust.

Achieving this tactile balance begins with pulp quality and fiber treatment. Virgin pulp tends to offer more softness, but blending with refined recycled fiber can add a firmer body. However, it's not only about material—it's also about how the fibers are processed. The creping process adds micro-wrinkles to the surface, which enhance softness while increasing bulk.

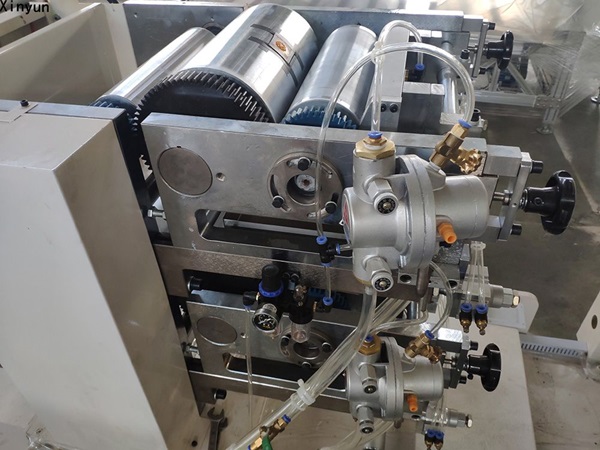

On the production side, this level of control over texture is realized through machines equipped with fine creping blades, surface smoothing rollers, and moisture calibration. For instance, consistent calendering pressure ensures the surface doesn't end up too glossy or too brittle. Napkin paper machines with intelligent tension feedback systems help maintain uniform texture across large production volumes.

Additionally, folding format and ply count contribute to tactile feel. Napkins that are folded using servo-controlled folding arms maintain more predictable pressure distribution, preserving the softness without flattening the paper unnecessarily.

Softness alone doesn't cut it. A napkin that can't absorb moisture is essentially just decorative. High-quality napkin paper must have strong absorbency to handle oils, sauces, and liquids without disintegrating.

In practical terms, absorbency is more than a lab test. A napkin should soak up sauce from a plate without breaking, handle moisture from cold drinks, and still retain some dryness after the first use. Low-grade napkins often create a smear instead of a clean wipe, forcing users to grab more. A high-quality napkin locks in the mess, minimizes usage, and stays intact until the job is done.

The science of absorbency lies in fiber porosity, layering, and embossing. Pulp that's too heavily refined may compact and resist fluid penetration. Conversely, loosely structured sheets absorb quickly but tear easily. Multi-ply napkins solve this by layering different textures—outer softness, inner strength.

From a manufacturing standpoint, this is where machine capability becomes crucial. High-grade napkin paper machines offer dual-embossing systems that interlock layers using micro-patterns. These not only improve visual aesthetics but also create capillary channels that guide moisture through the layers.

Equally important is how the plies are bonded. Advanced equipment offers ply-bonding mechanisms that apply just the right pressure—enough to secure layers without compressing the absorbent structure. On machines with advanced bonding modules, these steps can be fine-tuned digitally, adapting in real time to pulp thickness and humidity.

Even the speed of the drying phase affects absorbency. Machines with precision Yankee dryer drums ensure that drying doesn't overharden the sheet, preserving the napkin's internal ability to hold moisture while still feeling dry to the touch.

Nobody likes a napkin that breaks apart after one wipe. High-quality napkin paper must remain intact during folding, packaging, handling, and use. Structural strength doesn't mean stiffness—it's about resilience.

Strength also means reliability across repeated folds, pulls, and contact with wet surfaces. A durable napkin opens without tearing, doesn't fray at the edges, and survives an entire meal in one piece. Users shouldn't have to think about the napkin failing—its performance should be invisible, built into every layer. That kind of quiet resilience is a key marker of top-tier product design.

Structural integrity is influenced by pulp blend, fiber bonding, and sheet thickness. Stronger napkins often use a base sheet with longer fibers and controlled wet-strength additives that improve durability without affecting biodegradability. However, too much bonding can make the napkin feel rigid or rough.

During manufacturing, strength is maintained through tightly calibrated tension controls. A machine that unwinds too loosely may cause wrinkles or tearing; one that feeds too tight may stretch or distort the paper. High-precision napkin lines use edge-to-center tension control with automated feedback to regulate sheet behavior.

Furthermore, the folding mechanism has a major role. Machines with air-assisted or servo-synchronized folding arms prevent undue stress on creases, reducing micro-tears. Many modern systems include tension buffers and servo-rotating blade assemblies that ensure napkins retain shape during high-speed runs.

Edge trimming is another subtle contributor. Clean-cut edges prevent fraying and preserve form in packaging. This requires ultra-sharp rotary cutters and self-cleaning blade systems that maintain consistency without operator intervention.

In the world of branding, a napkin is a miniature billboard. Whether it's a café logo, a wedding design, or a restaurant's custom pattern, printed napkins serve both aesthetic and promotional purposes. But only when the print is sharp, consistent, and safe.

When done well, printing can turn a napkin into a subtle brand ambassador. The logo isn't just a mark—it should feel part of the paper itself, resisting smears from fingers or condensation. Color should remain vibrant after folding, and lines should stay sharp even on textured surfaces. Cheap prints fade fast or transfer ink; a premium napkin preserves identity from pack to use.

High-quality napkin paper needs to hold ink without bleeding or smearing. That depends on both surface treatment and ink compatibility. Papers treated with a slight surface sizing hold pigment in place while allowing fast drying. Without this, even the best design can appear dull or blurry.

This level of fidelity is only possible on machines with integrated flexographic printing units. These systems apply ink directly onto the napkin during production, using food-grade, water-based inks. They maintain image precision through synchronized register controls, ensuring the print aligns perfectly with the folds and embossing.

Multi-color printing requires precise drying intervals. High-end machines feature infrared or air-drying stations that solidify ink before the next fold or roll, preventing offset or smudging. Moreover, print pressure must be consistent across varying paper speeds—a feature achievable only with digital control panels and servo-adjusted rollers.

Color fastness isn't just about looks—it's about hygiene. Inadequate ink setting can result in color transfer to hands or utensils. Equipment that enables low-ink transfer rates and precise ink viscosity control helps maintain both safety and clarity.

A napkin's fold is its presentation layer. Whether stacked in a dispenser or set on a table, the first visible detail is how cleanly and uniformly the napkin is folded. Wrinkled or misaligned folds instantly undermine perceived quality.

Well-folded napkins don't just look good—they handle better. They pull cleanly from dispensers, open with one smooth motion, and sit flat on plates or in laps. Poor folds result in clumping, misalignment, and wasted paper. High-quality napkin paper holds shape without stiffness, presenting itself with quiet order and precision.

Fold consistency depends on precision folding plates, timed air jets, and servo-assisted synchronization. A napkin folded too early may crumple; too late and it loses alignment. Machines with programmable folding formats—1/4, 1/6, 1/8—and digital repeatability ensure every napkin in a stack looks identical.

Automated edge control and anti-static devices play subtle but crucial roles. They prevent napkins from clinging together or misaligning during high-speed stacking. In markets like hotel and airline service, this kind of consistency directly impacts brand reputation.

Some folding systems also offer easy switchovers between flat-folded and interfolded formats. This adaptability supports private label packaging or retail-grade napkin production—scenarios where visual symmetry is key.

Embossing isn't just visual—it's functional. It can add strength, control ply bonding, or serve as a branding element. The key lies in balance: embossing that is too shallow adds no value, while overly aggressive embossing can damage paper structure or feel intrusive.

From a user's perspective, embossing is subtle but powerful. A soft quilted pattern gives the illusion of thickness and plushness. Embossed logos suggest brand care. Even slight edge embossing can help the napkin hold its fold better. When patterns are clean and consistent, they elevate the sensory and visual experience without drawing attention to themselves.

Modern napkin embossing involves steel-to-rubber or steel-to-steel roller sets, adjustable in both depth and width. Patterns are transferred with controlled pressure, sometimes combined with heat or micro-texturing. Machines with dual-head embossing can apply border decoration and core bonding simultaneously, enhancing visual and structural design in one pass.

Many producers now use custom embossing plates with branding—logos, seasonal graphics, or icons. Machines that allow rapid plate swapping and pressure control make this viable even for mid-sized batches.

Embossing also improves hand-feel. A napkin with a light quilted pattern feels thicker and more absorbent, even if the actual weight is the same. But that illusion only works when the pattern is clean and symmetrical—something only high-grade machinery can reliably deliver.

Since napkins come into contact with the face, lips, and hands, safety is paramount. High-quality napkin paper must be manufactured in clean, contaminant-free environments using certified materials and food-safe inks.

A napkin should never leave doubts about hygiene. Users instinctively notice things like smell, surface cleanliness, and packaging seal. A napkin that arrives lint-free, odorless, and neatly packed reinforces trust—especially in food service. Consistency in appearance and handling is a critical, if unspoken, part of perceived cleanliness.

From a production standpoint, hygiene begins with material handling. Closed-loop feeding systems prevent airborne dust. Stainless steel contact points, washable conveyors, and isolated ink reservoirs reduce microbial risk.

Machines that support inline vacuum cleaning, self-lubrication, and automated filter change minimize downtime while maintaining sanitary conditions. For example, sensors can detect pulp contaminants and trigger bypass streams, ensuring only clean material enters the converting line.

In addition, consistent packaging plays a part in hygiene. Packaging units integrated with the napkin line—especially those offering heat sealing or plastic film application—protect the napkin from moisture, dust, and handling damage during transport.

Sustainability is no longer optional—it's expected. Consumers increasingly demand products that align with their environmental values, and napkins are no exception.

The best eco-friendly napkins perform like any other—soft, strong, and absorbent—without asking the user to compromise. They don't feel flimsy or rough. Instead, they demonstrate that sustainability and quality can coexist. This perception matters as much as any certification, especially to consumers making values-based purchasing decisions.

High-quality napkin paper today often includes FSC-certified fibers, chlorine-free bleaching, and water-saving pulp processes. But manufacturing plays a crucial role in extending this responsibility beyond material selection.

Energy-efficient equipment equipped with low-tension unwinding, regenerative braking, and minimal heat loss drying drums help reduce carbon impact. Smart water recycling systems and fiber recovery modules further close the loop in modern plants.

Automation contributes to waste reduction. Machines with automatic rejection of misaligned or defective sheets reduce overproduction and rework. Multi-batch programming allows for short runs with minimal downtime, supporting smaller, sustainable orders.

While the right pulp blend and finishing determine how a napkin performs, it's the precision of modern machines that brings these qualities to life. For brands aiming to meet premium standards, Xinyun Machinery provides advanced napkin paper machines that ensure every sheet meets the mark.

Contact us at [email protected] or visit www.xinyun-engine.com

By continuing to use the site you agree to our privacy policy.