Copyright © 2025 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map

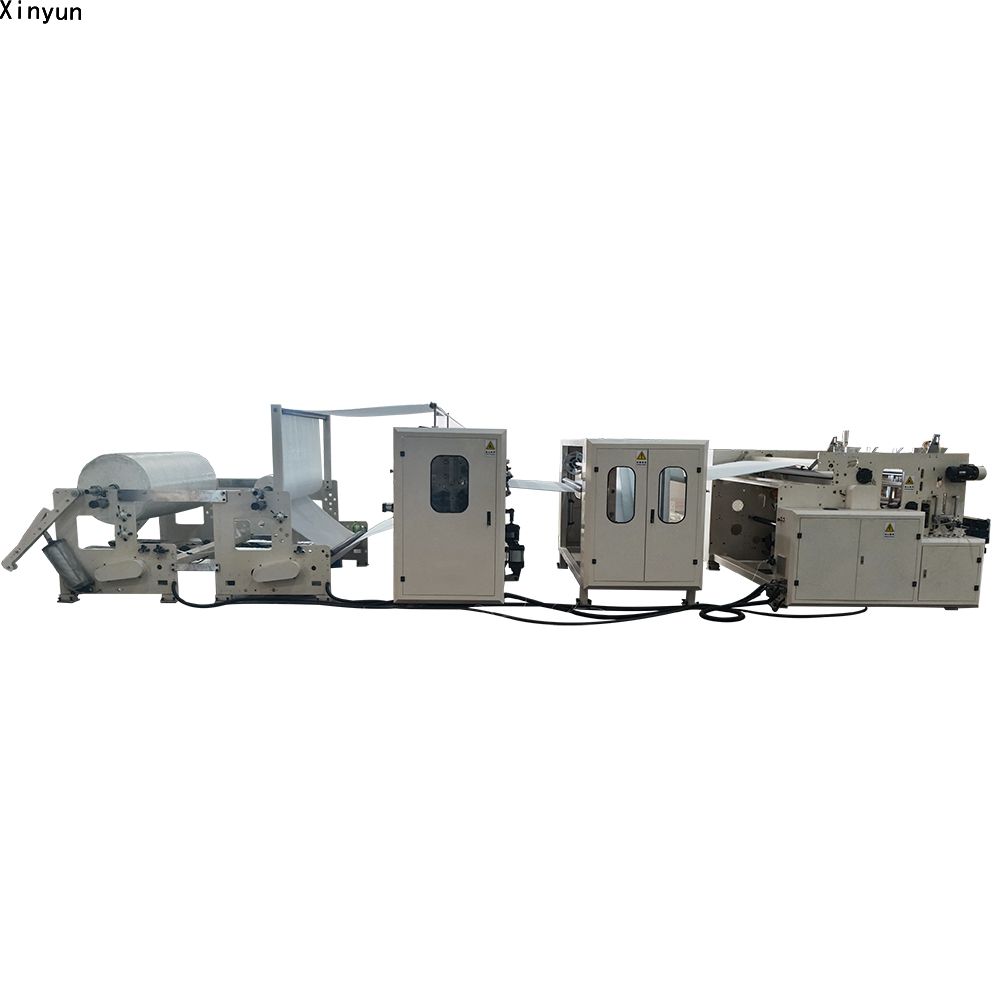

When producing premium toilet paper or kitchen towel rolls, adding glue lamination plus perforation into the rewinding process delivers significant advantages. A glue lamination toilet paper perforating machine integrates multiple functions—lamination, perforation, embossing or texturing, and rewinding—into a compact, automated workflow. Below, we explain how it works, what key benefits it delivers, and real‐world use cases.

This type of machine is a converting line module (or integrated line) that performs:

Glue lamination (bonding two layers or reinforcing parts, or applying glue for tail or edge bonding)

Perforation (cutting tear lines so sheets can be torn off cleanly)

Rewinding / Log forming (finishing rolls to size, core feeding, trimming, and sealing)

Often it also includes embossing (full or edge) and PLC-controlled automation (core feeding, edge trimming, touch screen HMI, etc.). Machines like the XY-TQ-B Automatic Glue Lamination Toilet Paper Kitchen Towel Rewinding Machine are good examples.

From product data (Xinyun and others), typical technical specs and features include:

Speeds of 180-230 m/min for high throughput.

Jumbo roll widths up to 2800 mm (customizable) for large-scale production.

Adjustable perforation distance (for example, 4 blades with 90-140 mm, 2 blades with 180-280 mm) to produce different sheet lengths.

Wall-type or stable frame / structure to reduce vibration and maintain alignment at high speeds.

Edge trimming, tail glue spraying, log sealing, core feeding. These reduce waste and enhance finish.

Here are the advantages buyers and manufacturers gain from using these machines:

| Benefit | Explanation |

|---|---|

| Improved Strength & Product Quality | Glue lamination reinforces rolls (plies or tail/edge glue), improving durability—important for kitchen towels or heavier bathroom rolls. |

| Better Tearability & Clean Finish | Perforation ensures sheets can be torn cleanly; with glue lamination and trimming, edges look more uniform. |

| Reduced Waste | Automatic tail glue and trimming avoid messy tails or uneven edges; lamination helps reduce shortcut waste caused by poorly bonded or weak rolls. |

| Flexibility & Versatility | Adjustable perforations and lamination modules allow one machine to serve multiple product types: toilet paper, kitchen towel, reinforced rolls. |

| Higher Throughput & Efficiency | Combining lamination, perforation, and rewinding in one unit reduces handling, labor, and production time. Speeds of ~200 m/min are achievable. |

| Enhanced Brand Value | Products with lamination or reinforced tails, clean perforations, and good finishes are perceived as premium in many markets. |

To illustrate how this works in practice, here are a few real or typical cases (drawn from Xinyun’s and related machines) where glue lamination + perforation modules have been applied successfully:

Xinyun’s XY-TQ-B Glue Lamination Machine used for both toilet paper and kitchen towel rolls. It supports edge trimming, tail glue, automatic core feeding, and adjustable perforation distances. It is used in production lines needing both strength (folded or multi-ply rolls) and clean tear usability.

2800 mm Automatic Kitchen Towel Glue Lamination Machine by Xinyun: this model handles full width, performs embossing + perforation + glue lamination + rewinding, producing large kitchen towels with reinforced strength.

Jori Paper’s Glue Laminated Toilet Paper & Kitchen Towel Making Machine: their “Uninterrupted Continuity Color Glue Laminated Toilet Paper and Kitchen Towel Making Machine” includes a glue lamination unit, wall-type rewinding, automatic edge trimming, tail glue, and adjustable perforation — used by clients who want both roll strength and aesthetic/perforation quality.

While glue lamination + perforation machines are powerful, achieving optimal performance involves care in several areas:

Glue Quality & Application Control: Uniform glue application is essential—too much glue makes rolls stiff or prone to peeling; too little glue causes weak bonding. Use precise glue spray systems.

Tail Glue & Edge Trimming Accuracy: Leaving a correct tail length (often 10-18 mm) ensures re-rewinding is clean and reduces waste. Edge trimming ensures uniform roll edges which improves packaging and appearance.

Perforation Setup: The choice of blade types, spacing, and sharpening matters. Clean perforations reduce consumer complaints about tears.

Frame & Tension Stability: Especially with wide jumbo rolls or heavier lamination, machine structure must handle forces without vibration, and tension control across the width must be good.

PLC & Control System: Being able to adjust perforation distance, glue flow, speed, etc., via touchscreen or HMI helps adapt to different SKUs.

Maintenance & Spare Parts: Glue units, perforation knives, embossing rollers will wear. Ensuring good spare parts availability and maintenance is critical for uptime.

From the data and specs, Xinyun machines with glue lamination + perforation modules stand out because:

They have wide jumbo roll width options (up to ~2800 mm), enabling large capacity lines.

High speeds (~180-230 m/min) allow efficient output.

Automation: edge trimming, tail glue, core feeding, sealing, PLC control etc., reduce manual labor and waste.

Customizable perforation distances and finished roll diameters give flexibility for different market needs.

A Glue Lamination + Perforation Toilet Paper Machine is not just an incremental upgrade—it’s a strategic investment for producers wanting both strength and premium feel, without sacrificing throughput or quality. For businesses producing both toilet paper and kitchen towel rolls, or producing rolls with higher strength / reinforced edges, these machines provide:

Stronger, better bonded rolls

Cleaner tear functionality

Reduced waste and labor cost

Versatility to adapt to different product specifications

For companies exploring tissue converting machinery, Fujian Xinyun’s offerings in glue lamination + perforation modules deliver precisely this value. If you want, I can also prepare a comparison table of Xinyun’s glue lamination perforation models vs competitors, or a downloadable spec sheet you can send to leads.

By continuing to use the site you agree to our privacy policy.