In modern tissue converting, combining glue lamination, color printing, and maxi-roll format in a single high-speed production line offers producers both premium product differentiation and operational efficiency. This article delves into what defines such a machine, its technical components, how it operates, and why it could be the right choice for your production requirements.

What is a High-Speed Glue Lamination Maxi Roll Color Printing Machine?

A machine of this type is designed to process large width “maxi” jumbo rolls of tissue paper (toilet paper / kitchen towel etc.), applying glue lamination (for strength, multi-ply bonding, or surface finish), printing color (patterns, branding, decorative motifs), and then rewinding into finished logs ready for further cutting/packaging.

Key capabilities typically include:

Working with jumbo roll widths (often 1.2 m up to ~2.8–3.0 m or more)

High processing speeds (often in the range of 200-230 meters/min or more for lamination / rewinding + printing steps)

PLC controls, automatic core feeding, edge trimming, tail gluing etc.

Adjustable perforation / embossing modules integrated

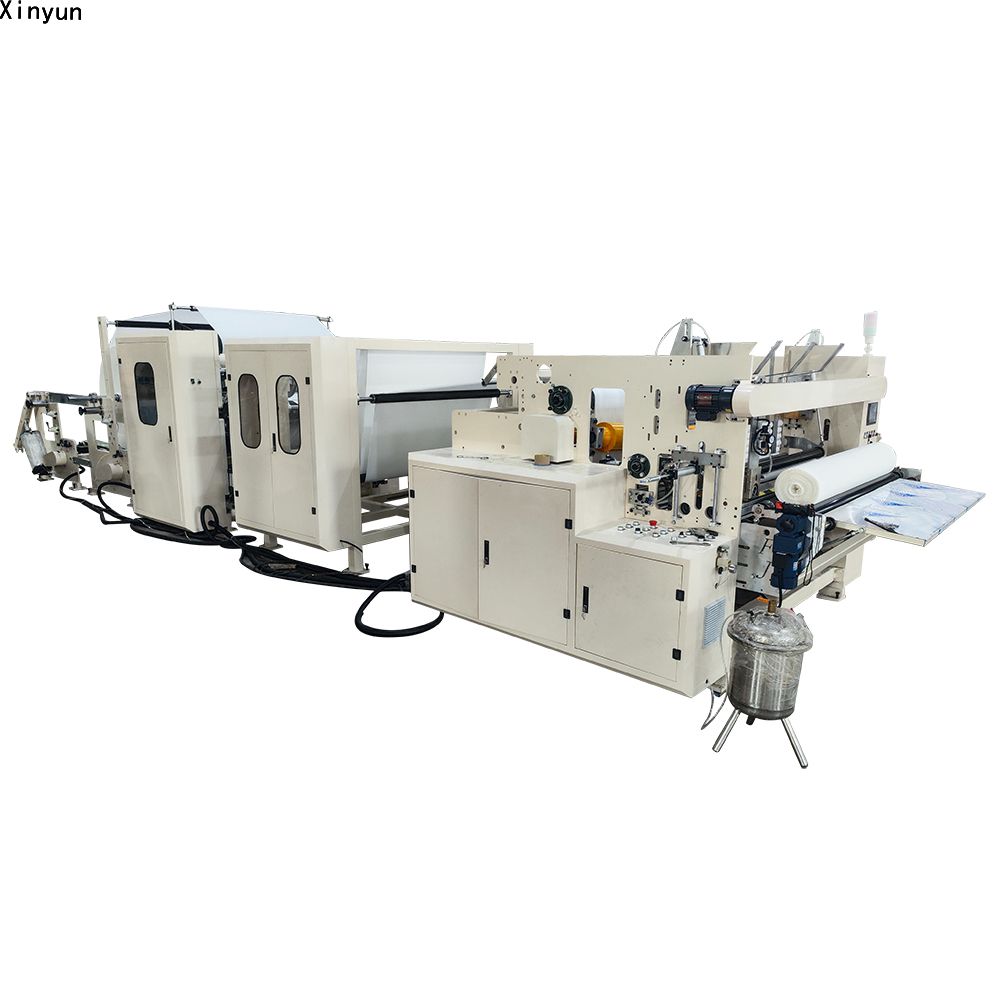

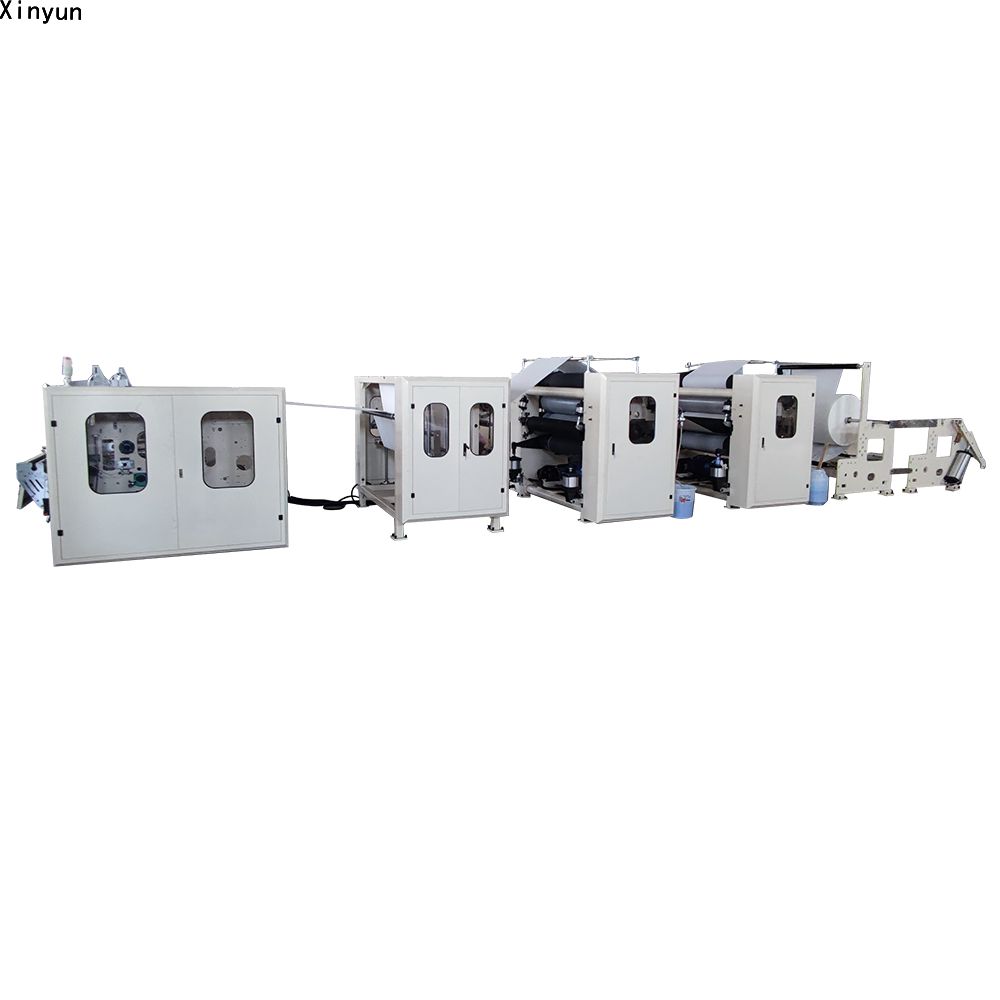

For example, the XY-TQ-B Automatic Glue Lamination Maxi Roll Paper Machine from Xinyun integrates Unreeling → Embossing → Perforating → Lamination → Rewinding → Tail-gluing → Edge trimming → Core loading in one line.

Also, for colour glue-laminated jumbo rolls, models like those by JORI Paper offer jumbo roll widths 1350-3000 mm, speed up to ~230 m/min, with finished log diameters from Φ90-280 mm.

Key Technical Features & Components

To understand what makes such machines effective and valuable, here are the technical insights into major components and design features:

| Component | Function / Design Points | Why It Matters |

|---|---|---|

| Unwinding / Jumbo Roll Stand | Wide back stands (2-3 stands), wall-type structure, independent adjustment per jumbo roll, pneumatic loading. | Stability and smooth feed are critical for color printing quality and consistent lamination. Uneven tension leads to print registration issues. |

| Glue Lamination Module | Application of glue (for ply bonding or surface coating), steel-to-rubber lamination rolls, point-to-point lamination options. | Lamination enhances strength (especially for kitchen towels or reinforced rolls), improves surface finish, and allows decorative or functional treatments. |

| Color Printing Unit | Flexographic printing or roll printing; optional multiple colors; rollers/ink control; may include printing before lamination to encapsulate color; speed matching with lamination section. | Color printing adds brand value and decorative differentiation; accurate printing requires synchronization with glue lamination and embossing to avoid misalignment or smudging. |

| Embossing / Perforation | Embossing rollers (point-to-point, steel/rubber), spiral knives (often 4-piece) for perforation; adjustable perforation distances. | Embossing improves texture and softness; perforation impacts tearability; both must align with printed pattern for premium appearance. |

| Rewinding / Finished Log Forming | Core feeding (with or without core), tail-gluing, edge trimming, log diameter control; often controlled via PLC / HMI. | Clean finish, minimal waste, reliable handling. The glue‐laminated layer and printed surface must not distort or misalign during rewinding. |

| Control Systems & Automation | PLC based, touch screen interface, fault feedback, parameter presets, automatic core loading; necessary sensors and tension control. | Ensures reproducible product quality, reduces operator error, facilitates faster changeovers between SKUs. |

Performance Ranges & Specifications

Based on public specs and your product line, typical performance metrics are:

Jumbo roll width: ~1200-2800 mm or even up to 3000 mm in larger models.

Finished log diameter: Φ70-Φ280 mm, inner core diameter Φ38-Φ76 mm etc.

Operating speed / line speed: ~200-230 m/min for many high-grade glue lamination + maxi roll lines. Sometimes slightly lower in lines with heavy printing or thick lamination.

Perforation distances: Adjustable to match product design (e.g. 100-150 mm or more) depending on required sheet size.

Control & power: PLC/HMI; motors sized per width; glue / lamination units; facility for edge trimming, tail gluing. Noise and precision expected to be high in premium models.

Benefits of Using This Combination

Integrating glue lamination + color printing + maxi roll format has multiple advantages:

Product Differentiation

Color printing plus lamination allows brands to offer decorative, premium rolls—improving shelf appeal and allowing higher margins.Enhanced Strength & Quality

Glue lamination improves durability, reduces tearing, especially in kitchen towel rolls or heavier tissue rolls; the print protected under lamination is less prone to smearing or damage.Economies of Scale

Maxi roll format (wider jumbo rolls) and high speed throughput reduce unit cost per roll. Also, fewer changeovers and automated functions save labor and reduce downtime.Reduced Waste

Edge trimming, tail glue techniques, accurate tension control reduce mis-wounds, shortcuts, imperfect edges. Designer patterns printed aligned across roll front and edges look better and reduce rejects.Versatility

Able to produce multiple SKUs: with/without core, different roll diameters, variances in perforation, different printing designs. Useful for markets with varying demand.

Application Cases

Here are some example / hypothetical cases where such machines are or would be ideal:

Large-scale maxi roll producers who want to enter premium markets (e.g., decorative prints, seasonal designs) can use one line to produce both standard white rolls and printed rolls.

Kitchen towel manufacturers using glue lamination for strength and printing for branding (patterns/floral etc.), able to offer both plain and printed rolls in same line.

Regional distributors in countries where packaging aesthetics matter (e.g. tourism, retail sectors) and customers are willing to pay more for attractive rolls.

OEM/Contract manufacturers who supply multiple brands: printing capability allows customizing branding for different customers without needing entirely separate lines.

Challenges & Considerations

While powerful, such machines need careful planning and attention. Some points to watch:

Ink / Printing Quality & Drying

Printing must be dry / stable before lamination or risk smears; color registration must align with emboss/perforation, demanding high precision.Glue / Lamination Materials

Adhesive strength, compatibility with paper & inks; glue streaks or uneven lamination can degrade print.Structural Stability & Vibration Control

Wide jumbo rolls and high speeds cause dynamic forces; build quality (wall-type frame, stable drives, quality bearings) vital to maintain print alignment.Operational Costs

Printing adds ink, extra maintenance, color changes; lamination and glue consumption; cleaning.Changeover Flexibility

If you're producing many SKUs (different print designs, roll sizes), need modular, quick-change parts and parameter presets.

Why Fujian Xinyun Machinery’s Solution Stands Out

Based on your product line and public specs:

The XY-TQ-B line supports glue lamination, edge trimming, tail glue, high precision spiral knives, jumbo widths up to ~2800 mm.

Xinyun also offers high-speed glue lamination kitchen towel / maxi roll machines (e.g., “Glue Laminated Kitchen Towel Paper Making Machine (High Grade)” with 1350-3000 mm widths, speed up to ~230 m/min) that combine lamination + printing or aesthetic finishing.

They provide PLC + HMI, allowing parameter control of printing, lamination, perforation, roll content. Buyers can likely specify custom widths, roll diameters, print patterns.

Conclusion

A High-Speed Glue Lamination Maxi Roll Paper Color Printing Machine is a high-value investment for tissue paper manufacturers seeking to combine strength, aesthetics, and volume. When properly designed—ensuring stable frame, quality printing & lamination units, precise control, waste minimization—it can deliver both premium product offerings and lower per-unit costs.

If you are evaluating your next converting line, consider your market’s demand for decorative or printed rolls, the SKU variety, and how much incremental cost printing & lamination adds versus the pricing power you gain. Fujian Xinyun’s product range aligns closely with these needs, offering machines capable in size, speed, and functionality. For personalized spec sheets or project planning, reach out to us today.