Copyright © 2025 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map

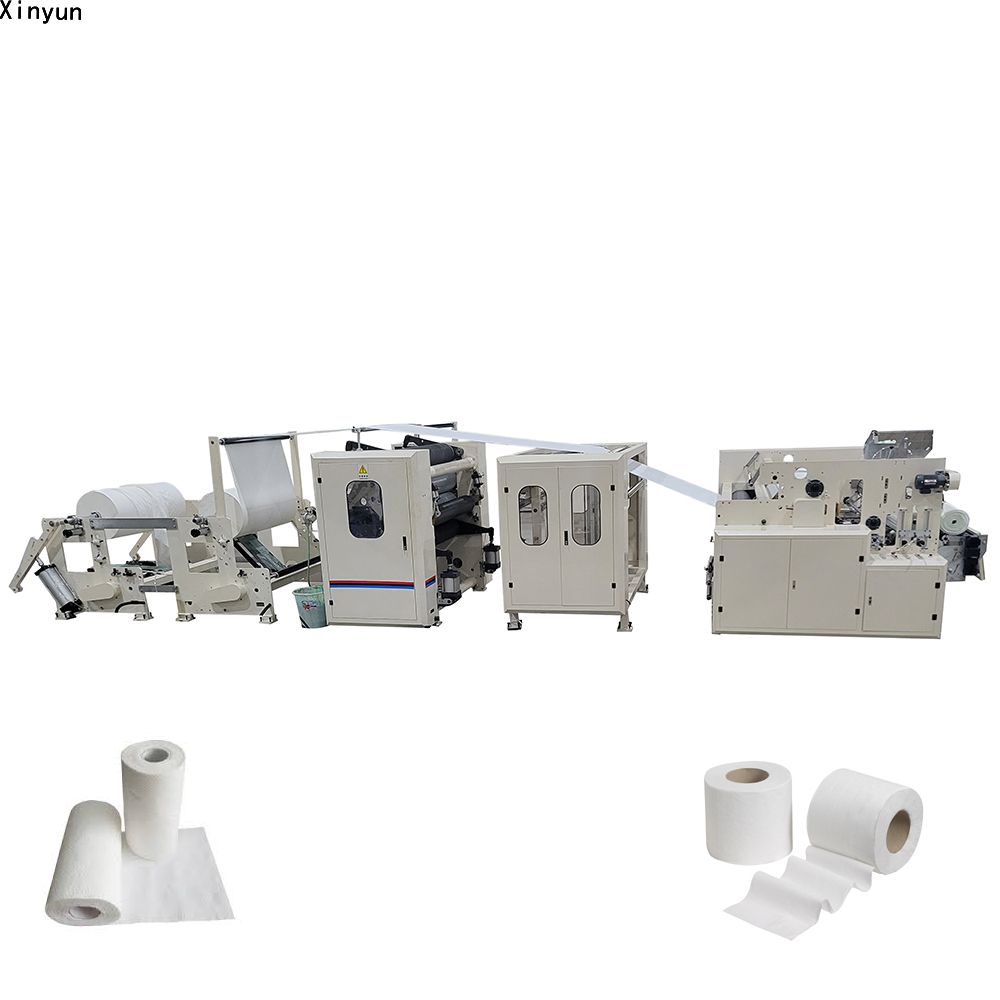

Producing high-quality toilet paper and kitchen towel rolls requires precision machines that can emboss, perforate, and rewind material efficiently. The automatic perforating + embossing + rewinding machine (often used in lines like XY TQ B or similar models) integratesthese key processes into a seamless workflow. In this article, we break down how this combined machine works, what components are involved, and how it supports both toilet and kitchen towel roll production.

The combined machine integrates three primary operations:

Embossing — Imprinting texture/patterns on paper to improve softness, aesthetics, and absorbency

Perforating — Cutting a dotted line into the paper so sheets can be torn off cleanly

Rewinding — Rolling the processed paper into finished consumer rolls (or “logs”), with core or coreless options

In a typical production flow, jumbo roll stock (often already pre-processed or partially processed) is fed into the machine, then goes through embossing, then perforation, then into the rewinding module where trimming, tail gluing, and core loading occur. Finally, the logs are pushed out to subsequent cutting or packaging lines.

Xinyun offers such a machine under “Automatic perforating embossing rewinding toilet paper kitchen towel paper making machine.”

To understand how the machine works, let’s look at its major modules:

Jumbo rolls are placed on back stands or unwinders, often in triple or multiple back stands with pneumatic loading.

Independent tension control per roll ensures consistent feed and avoids misalignment or wrinkles.

The embossing unit (steel-to-rubber, or steel-to-steel) applies patterns to the paper.

It can be full embossing (across the full width) or edge embossing (pattern only on edges) depending on product design.

Embossing improves softness, thickness perception, and absorbency.

After embossing, the paper passes through perforating knives (spiral or circular blades).

2-blade or 4-blade configurations are common.

The perforation distance (sheet length) is adjustable (for example, 80–160 mm or more) depending on target sheet length.

The perforating blades are high-precision to ensure clean tear lines, low noise, and minimal paper waste.

Perforation usually works pneumatically or mechanically.

Once embossed and perforated, the paper is wound into finished rolls (logs).

The rewinding section often includes:

• Edge trimming (cutting off imperfect margins)

• Tail gluing & sealing (applying glue to join ends neatly)

• Core loading (if using cores) or coreless winding

• Automatic log pushing or ejection to next process

The machine may leave a 10–18 mm tail for easier re-rewinding later and to avoid waste.

PLC control ensures that log diameters, tension, and winding behavior maintain consistency.

The entire machine is controlled via a PLC (Programmable Logic Controller).

Operators use a touch screen (HMI) to set parameters such as embossing pressure, perforation pitch, roll diameter, etc.

Fault detection systems (paper break sensors, tension alarms) help reduce downtime.

Many machines support “with-core” and “coreless” modes, giving flexibility in finished product types.

While the same machine can often serve both purposes, some adjustments and configurations differ depending on whether you are making toilet paper or kitchen towel rolls:

| Feature | Toilet Paper | Kitchen Towel |

|---|---|---|

| Paper Weight & Thickness | Lighter GSM, more focus on softness and faster dissolving | Heavier weight, higher wet strength, may require glue lamination or ply bonding |

| Embossing Style | Softer, more delicate embossing patterns to maintain comfort | Deeper or more aggressive embossing to boost absorption and surface texture |

| Perforation Settings | More frequent, shorter sheet lengths | Longer sheets, fewer perforations but sturdy tear lines |

| Core / Coreless Mode | Coreless is often used for premium toilet rolls | Core mode is common since kitchen towel rolls are heavier |

| Tail Glue & Sealing | Minimal adhesive, neat sealing | Stronger adhesive to withstand wiping and handling |

| Frame & Drive Strength | Standard structural strength is usually sufficient | Heavy-duty frame and better drive motors may be needed due to higher tension and heavier logs |

Xinyun’s specification for its perforating embossing rewinding machine supports both toilet and kitchen towel modes, with options for with-core or coreless rewinding, embossing, tail gluing, etc.

While specs vary by model and customization, typical ranges are:

Jumbo roll width: 1,200 mm to 2,800 mm (or more, if customized)

Finished roll diameter: Φ70 mm to Φ280 mm or similar range

Finished core diameter: φ38 mm to φ76 mm

Machine speed: 180–230 m/min (some machines are specified in this range)

Perforation distance options: e.g. 4-blade 90–150 mm, 2-blade 180–300 mm (adjustable)

Power & pneumatic: The machine requires compressed air (3 HP or more) and power depending on model (5.5 kW up to more for heavy versions)

Control system: PLC + HMI interface, fault alarms, automatic core loading, automatic tail gluing & trimming integrated.

Using such an integrated machine offers several advantages:

5.1 Efficiency Through Integration

Combining embossing + perforation + rewinding in one line reduces material handling, time delays, and labor.

5.2 Consistency & Quality Control

Because the three operations are synchronized, the result is more uniform: embossing patterns align with perforations, tails are neat, and log formation is consistent.

5.3 Flexibility Across Products

The machine can adapt to both toilet paper and kitchen towel production with minor adjustments—enabling you to diversify SKUs in one setup.

5.4 Reduced Waste & Material Use

Tail gluing, trimming, and controlled winding reduce waste (shortcuts, miswinds). The design often leaves minimal margins.

5.5 Lower Labor & Operational Cost

Automation minimizes manual intervention in key steps, improving throughput and reducing dependency on skilled operators.

5.6 Customization & Scalability

Many brands offer optional modules (e.g. glue lamination, coreless mode, embossing styles) that can be retrofitted or upgraded.

5.7 Better Market Positioning

Rolls with better embossing texture and clean perforations improve end-user satisfaction, which can help in branding, especially for premium products.

To get the full value from such a machine, you’ll want to plan carefully:

Layout & Footprint: Ensure enough floor space, width clearance, and access for maintenance.

Material Compatibility: Choose paper stocks, embossing rollers, glue types that match your target product.

Operator Training: Though automated, operators must be trained to change parameters, handle faults, maintain blades and glue systems.

Spare Parts & Maintenance: Have spare embossing rollers, perforation blades, glue nozzles in stock to reduce downtime.

Switching Between Products: Minimize changeover times by designing modular setup (quick install embossing modules, adjustable perforation blades, preset parameter sets).

Quality Monitoring: Use sensors for paper break detection, tension variation, log diameter control, to maintain quality.

Here’s a simplified outline of how a sheet moves through the machine:

Unwind jumbo roll → feed into the line

Embossing stage — emboss roller imprints pattern

Perforation stage — knives perforate sheet at intervals

Rewind & log forming — tail gluing, trimming, core (or coreless) forming

Eject log → send to cutting or packaging unit

This integrated process ensures that embossing, perforation, and winding happen in harmony, preserving alignment and minimizing handling.

An Automatic Perforating + Embossing + Rewinding Toilet & Kitchen Towel Machine is a pivotal component in modern tissue converting lines. By combining three core processes into a synchronized workflow, it offers efficiency, consistency, flexibility, and cost savings. While implementation requires careful planning (layout, parameter settings, materials, maintenance), the ROI and product quality gains are substantial—especially for manufacturers who wish to produce both toilet rolls and kitchen towel rolls with one adaptable platform.

By continuing to use the site you agree to our privacy policy.