Copyright © 2025 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map

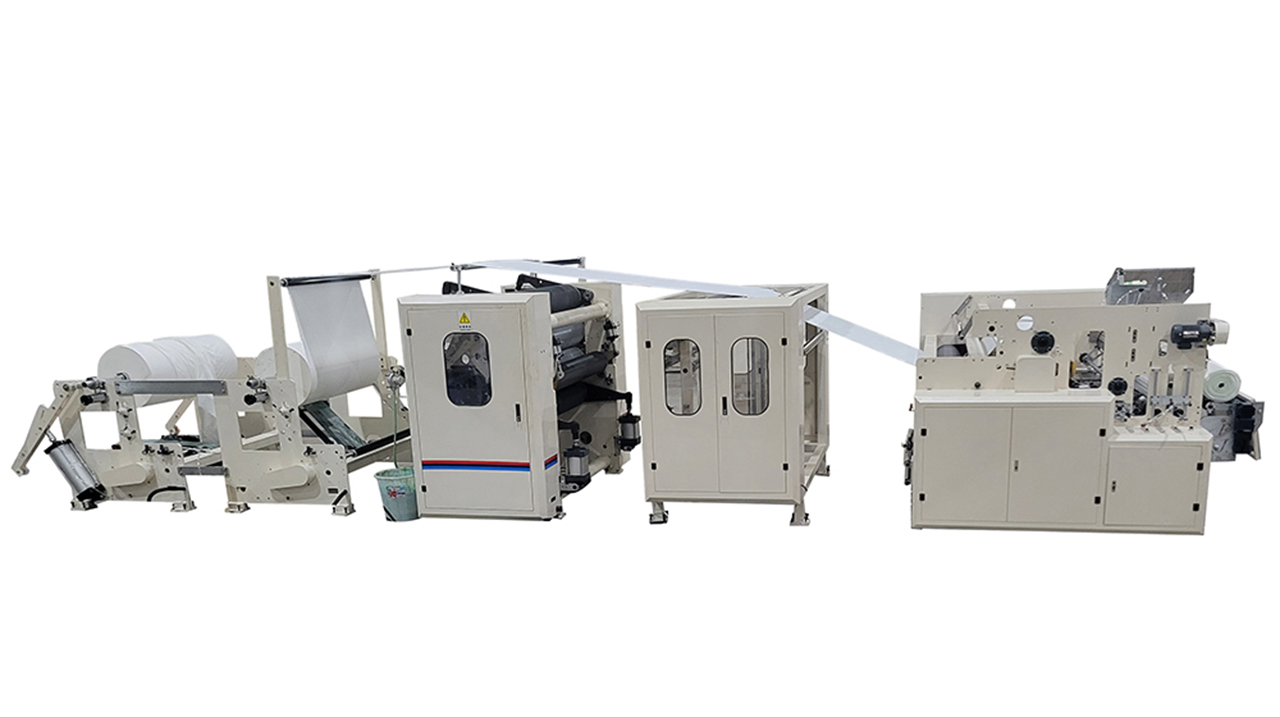

Automatic toilet paper rewinding machine is for toilet paper roll processing. Machine have core feeding unit, can do both with and without core. Raw material from jumbo roll after full embossing or edge embossing, then perforation, end cutting and spray the tail glue become a log. Then it can working with cutting machine and packing machine to become the finished products. The machine is controlled by PLC, people operate it through touch screen, the whole process is automatic, easy to operate, lower the man cost. And Our machine can special-made according to clients’ requirements. The production process is: Unreeling — Embossing — Perforating— Lamination— Rewinding— Tail-gluing— Edge trimming---Automatic core loading.

Automatic glue lamination small bobbin paper making machine XY-TQ-B

Automatic toilet paper rewinding machine is for toilet paper roll processing. Machine have core feeding unit, can do both with and without core. Raw material from jumbo roll after full embossing or edge embossing, then perforation, end cutting and spray the tail glue become a log. Then it can working with cutting machine and packing machine to become the finished products. The machine is controlled by PLC, people operate it through touch screen, the whole process is automatic, easy to operate, lower the man cost. And Our machine can special-made according to clients' requirements.

Function and Features:

1. Automatic core feeding system, automatic log pusher after rewinding, then rewinding the new log again.

2. Automatic edge-trimming, core feeding, glue spraying and sealing synchronously in one time. Leaving 10-18mm tail, easy to rewind again, so reducing shortcut waste and save the cost.

3. Adopts international advanced PLC programmable controlling technique, man-machine interface operation, data set and parametric fault shows on touch screen.

4. Adopts 4 pieces high Precision spiral knives, low noise, clear perforation, adopt gearbox to have bigger range.

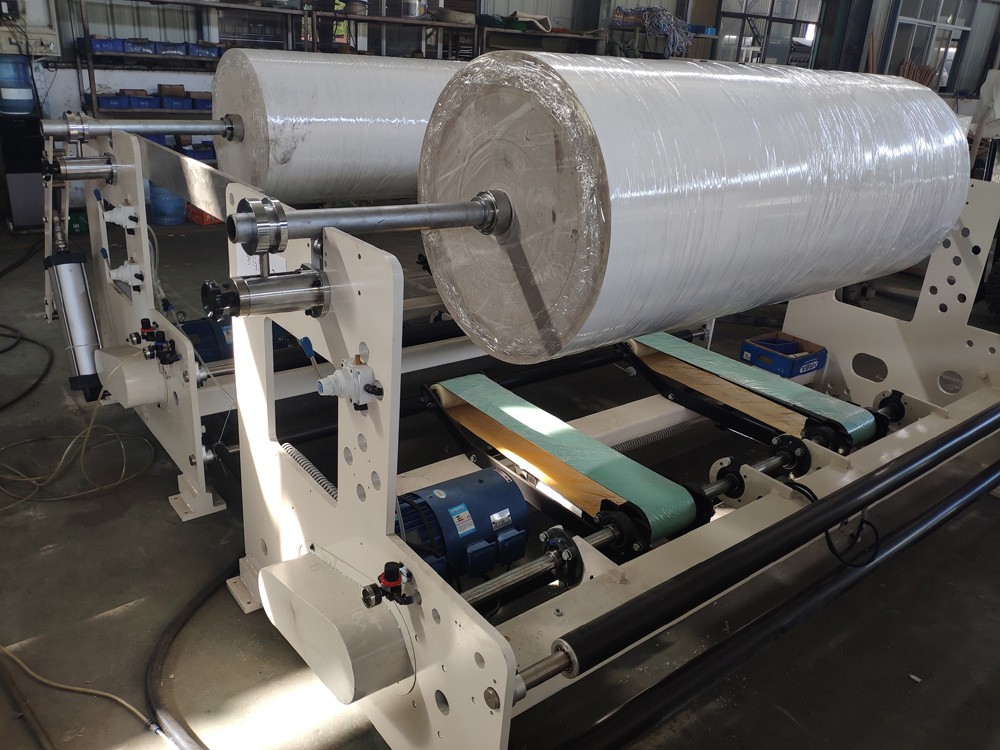

5. Three horizontal type back stands, pneumatic loading system, with wide driving flat belts; each jumbo roll can be adjusted independently.

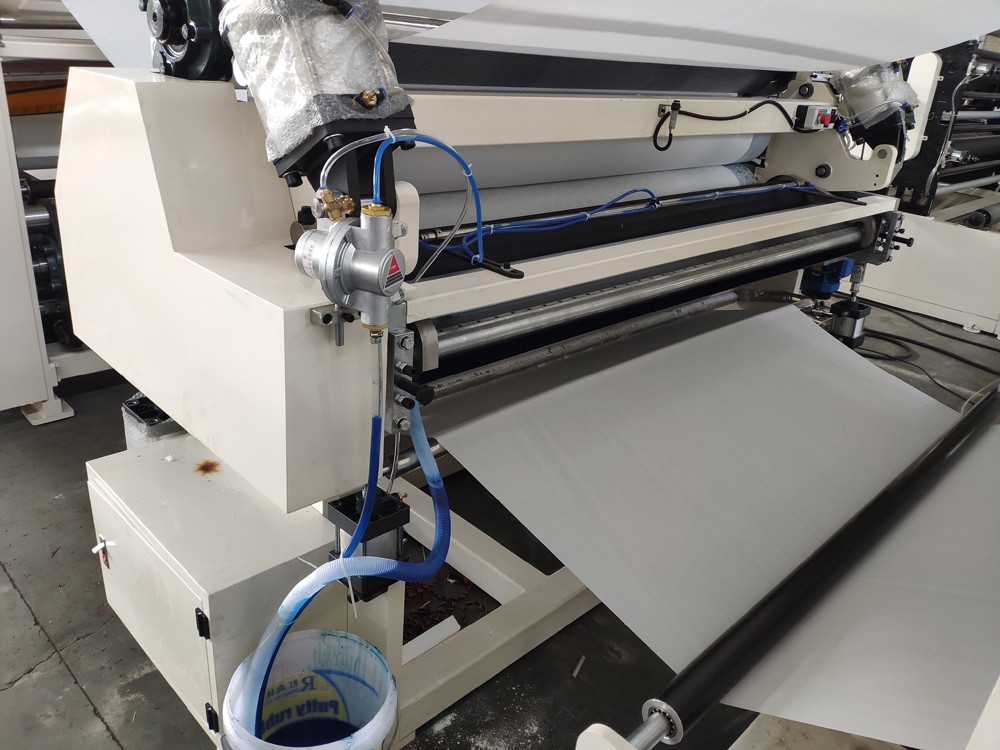

6. Embossment Unit: adopt point to point embossing rollers, making the two layers match well, the paper is soft and has clear patterns

7. Adopt jogging switches for wearing the paper, easy and safe to operate.

Main Technical Parameters:

Main Technical Parameters:

| The width of jumbo roll | 1200-2800 mm |

| The diameter of jumbo roll | 1200 mm(Other size can be specified) |

Jumbo roll inner core diameter | 3inches(76.2mm) |

Finish product diameter | Φ70-φ280mm |

Finish product Inner core diameter | φ38-φ76mm |

Perforation distance | 4 anvil Blades 90-150mm;2 anvil Blades 180-300mm |

| Speed | 180-230 m/min |

| Embossing device | Steel to rubber |

Pneumatic system | 3HP Air Compressor, Minimum Pressure: 5kg/cm 2Pa(Provide by user) |

Rewinding Unit | With core or coreless |

Jumbo roll standard

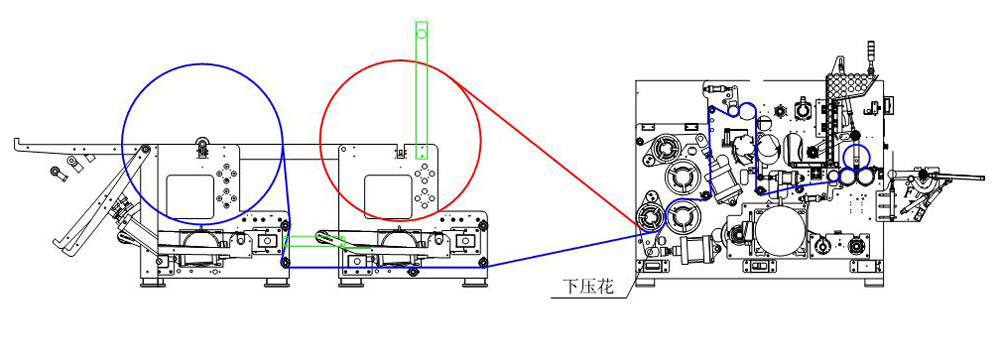

Doctor blade gluing lamination device Embossing device

Embossing device

Perforating device

Tail-gluing— Edge trimming

Our service

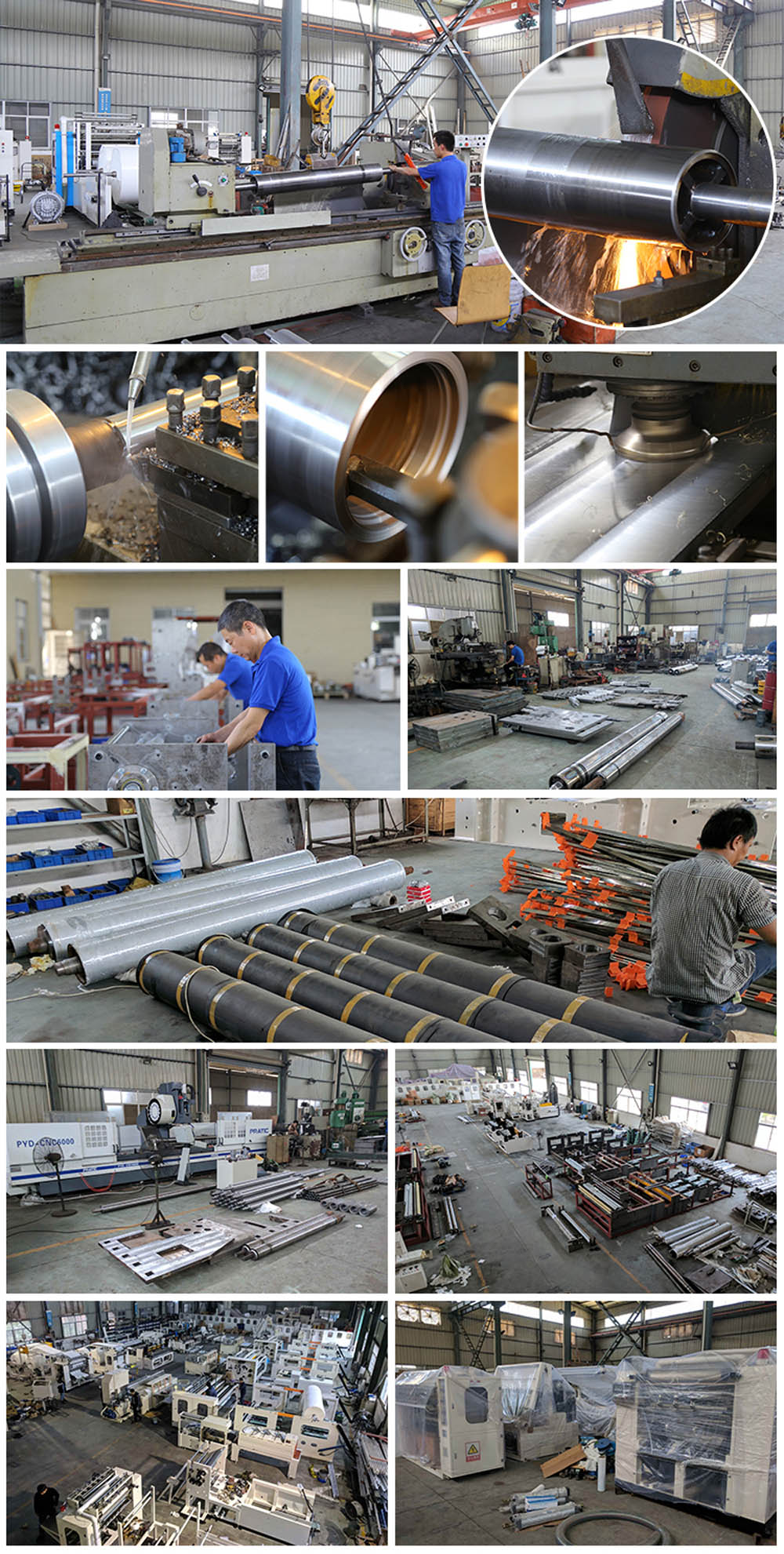

Workshop

Our company

Professional supplier of:

1) Toilet Paper Machine (1.2m--2.8m width of parent roll, Customize Service)

2) Roll Kitchen Paper Towel Machine (1.2m--2.8m width of parent roll, Customize Service)

3) Facial Tissue Machine (2-8 output lanes)

4 )Napkin Paper machine(L-fold, 1/4-fold, 1/6-fold, 1/8-fold and other multi-fold type)

5) Hand Towel Paper Machine(C-fold, V-fold and N/Z fold type)

6) Pocket Tissue Machine(mini and standard size)

7) All kinds of Tissue Paper Cutting and Packing Machine

8) Another Household Paper Equipments and Production Line.

Welcome to contact us to get more details !

We can design the machine according to your request.

By continuing to use the site you agree to our privacy policy.