Copyright © 2025 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map

High speed full automatic jumbo roll slitting and rewinding machine is the raw material at high speed slitting system, from single ply can be slit and rewinded into two, three or four ply paper with various widths, for the production of napkin, hankies, facial or sanitary napkins. The machine is featured of good performance, compact structure, and stable running, and easy operation. The finished products have good winding profiles, which make it a good equipment for the paper mills and textile factories, and a high reputation from the customers.

Newest mother jumbo roll paper slitting machine XY-XX-A

High speed full automatic jumbo roll slitting and rewinding machine is the raw material at high speed slitting system, from single ply can be slit and rewinded into two, three or four ply paper with various widths, for the production of napkin, hankies, facial or sanitary napkins. The machine is featured of good performance, compact structure, and stable running, and easy operation. The finished products have good winding profiles, which make it a good equipment for the paper mills and textile factories, and a high reputation from the customers.

Main function and feature

1. Adopt the widen belt on back-stand to increase the friction when feeding paper.

2. Synchronous belt transmission, make it stable-running and less noise even though at high speed operation.

3. Equipped with newly fasten unit, making it is convenient to adjust the raw material.

4. With the function of pneumatic paper loading, edge vacuum suction.

5. Automatic finished roll discharging, Solve the deformation caused by falls paper phenomenon, save the labor force. (Optional)

6. Easy operation, the finished products have good winding profiles and clean cutter.

Main Technical Parameters:

| The width of jumbo roll | 1800-2800 mm |

| The diameter of jumbo roll | 1200 mm(Other size can be specified) |

Jumbo roll inner core diameter | 3inches(76.2mm) |

Slitting diameter | 1200 mm |

Finish product Inner core diameter | 76mm |

Slitting Width | Adjustable |

| Speed | 400-500 m/min |

Base paper core shaft | Air-shaft |

Rewinding System | Pneumatic timing rewinding |

Slitting System | Automatic slitting control |

Discharging Unit | Automatic discharging |

Edge Cutting Unit | 2.2KW Vacuum suction edge cutting 2.2 KW |

Power | Frequency conversion speed regulate 15KW |

Pneumatic system | 3HP air compressor, min. pressure 5kg/cm2pa ( provide by user) |

Our service

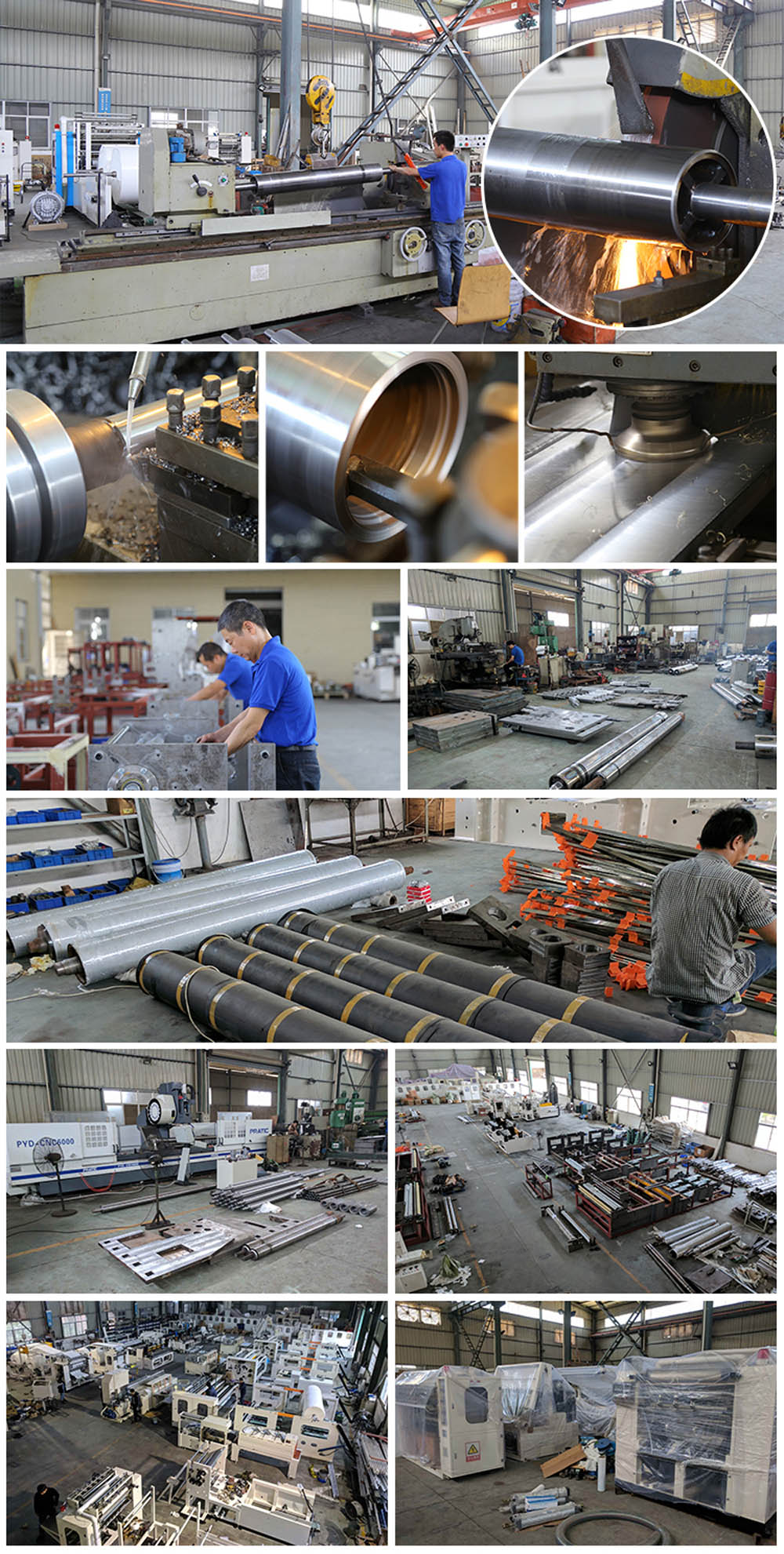

Workshop

Our company

Professional supplier of:

1) Toilet Paper Machine (1.2m--2.8m width of parent roll, Customize Service)

2) Roll Kitchen Paper Towel Machine (1.2m--2.8m width of parent roll, Customize Service)

3) Facial Tissue Machine (2-8 output lanes)

4 )Napkin Paper machine(L-fold, 1/4-fold, 1/6-fold, 1/8-fold and other multi-fold type)

5) Hand Towel Paper Machine(C-fold, V-fold and N/Z fold type)

6) Pocket Tissue Machine(mini and standard size)

7) All kinds of Tissue Paper Cutting and Packing Machine

8) Another Household Paper Equipments and Production Line.

Welcome to contact us to get more details !

We can design the machine according to your request.

By continuing to use the site you agree to our privacy policy.