Copyright © 2025 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map

n Safety Matter

This product is electricity and gas compound driving equipment, for purpose of safety of operators and equipment, please must hand over professional persons for installation and adjustment. Please carefully read where there is similar symbols such as “DANGER”,”ATTENTION”,etc in this manual. To avoid you and other human body life safety and equipment safety from damage, please use equipment safely and correctly. If user disobey following matters and give rise to person body injury(hurt,etc) and substance loss, our company will not bear any responsibility!

1.When electrocircuit lay out lines and equipment maintenance, must cut off Power Supply.

2. in order that whole equipment run safely, please must set safety electrocircuit device at the exterior of electrical equipment. Mistaken operation will perhaps give rise to accident.

3.Before start achine, must ensure that each performance organ act without interference.

4.Prohibit from altering any part of equipment privately without permission

Private alteration of equipment can perhaps give rise to unexpected accident. Please don’t alter equipment privately without permission from our company, or all human body injury or hurt and substance loss thus cause wil be completely taken responsibility by the person who alters(the person who alters will be responsible for all related results).

5.Prohibit from running for long period of time at high speed

Run for long period of time at running speed stipulated on equipment will cause equipment damage and lower usage life.

6.When installing equipment, should install Ground Protection, ground wire Resistance Value should be less than 4 ohms.

7.Compressed Air Source should be assured to be above 5Kgf.

8.Prohibit any part of person body from being near or touch running part when equipment is running.

Before start machine,please turn off equipment’s safety protection door. During process of equipment, Prohibit from any part of person body be near or touch running part. Or perhaps will give rise to fatal human body injury(hurt,etc)!

9.The asphalt felt on cutting knife roller should be added with edible oil or silicone oil instead of machine oil.

10. Prohibit from installing & using equipment in circumstance which doesn’t conform with related stipulation

Equipment is installed in circumstance which doesn’t conform with stipulation for usage, can not get performance and life designed, even give rise to unexpected accident, cause person injury and substance(material) loss.

11.When equipment is discarded as useless,please be as an industrial waste for disposal.

12.Our company product adopts wooden pallet packing, generally adopt forklift conveying

help you quickly master the usage and maintenance skill of the product to ensure product's long-term service. The product is continuously being upgraded and improved,f any difference from the User Manual occurs, it is subject to the actual function. Any correction and criticism are welcomed if any omission, defect and confusion in our edition.Equipment Brief Introduction

XY-OQ-7000A multi-colors napkin paper machine print various kind of colors and design on cut raw material, and to be square and rectangle napkin after embossment, folding and cutting.

Main Technical Parameter

1. Production Speed:100~150m/min

2. Machine Power:4.5KW (380V 50HZ)

3. raw material:

Single ply:≥17g/m²

Two plys:≥13g/m²

4.Jumbo roll paper specification:300×Φ1200mm

5. Final product opening size:300mm×300mm

Folding size:1/4folding 150mm×150mm(other specification and folding type , please order)

6. Overall size :5 m X1 m X1.6m

7. Equipment Weight:about 1.5T

Equipment Installation

clear spot(site) for installation;

Requirement for hoisting equipment: 1 piece of forklift. Check whether forklift performance conform with equipment hoisting requirement: balanced, satisfy maximum hoisting capacity and hoisting size;

Disconnect packing box,check equipment according to packing list, and check whether equipment has damaged,whether equipment scutcheon and safety symbol are fine.

During installation,please note that don’t damage equipment, and notice human body safety.

This equipment should be installed on solid and flat ground of concrete, before installing the Main Machine, the level of front & rear, left & right should be adjusted very well, make machine keep(remain) stable and flat. After machine is installed well, then firstly must check Fastening Screw of each part to see whether they are loose, if they are loose, then must tighten them accordingly. Also must check parts which should have Lubricating Oil for lubrication, if the Lubricating Oil is not enough, please add it in time. After finish the installation, then should re-check once again to ensure machine can run normally.

Note: don’t install machine at the following places, or will affect machine normal usage.

Place where Sun shines directly: if machine is installed at place where Sun shines directly or sunshine ray is strong, will make electric eye failure.

Place where temperature is too high or too low,space is too confined: the proper operation environment temperature is: 0~45℃;Humidity: without condensation(coagulate) water 10~90%RH value.

place where has epicentre

place near ventilation equipment and air adjuster’s air outlet.

Atrocious environment where has corrosive gas or dust thus don’t be suitable for machine usage and maintenance.

Operation and Production

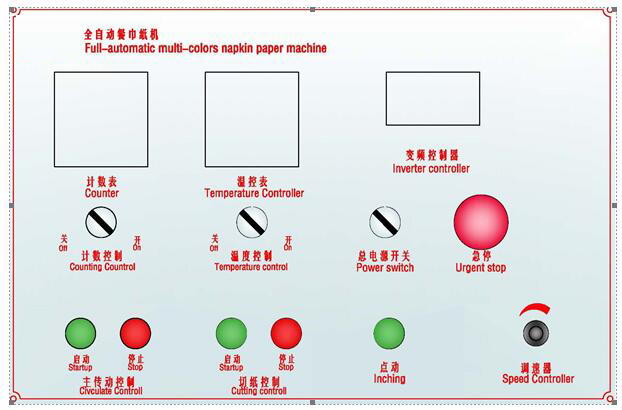

一、 Console sketch map

1Inverter controller

Can display current motor running frequency, the other parameter don’t change

2 Speed controller

Adjust equipment speed

3 Cutting paper control

Please start it after finished product transport to cutter position

4Counter

use to control the output of finished product.

5 Temperature controller

Use to control heat temperature of embossing up roller, in order to get good shape.

6 Emergency stop: used for emergency stop

7.point operation: used for intermittent operation of equipment

二、 Operation production

(一)

Before operation, first please confirm the following work have been finished:

1) Make sure equipment has been finish installation according to flow chart, and check up screw of each part.

2) Sure you have the correct power supply for equipment access: three-phase 380V 50HZ, and access to ground

3) Gas source for the device access :5-6kgf

4) Start air switch in mainframe electric cabinet, run the machine without load and check the direction of rotation is correct. If the equipment runs counter- clockwise , please check the connection again.

(二) Operation steps:

1. Please specify the size of the toilet paper holder placed. Adjust horizontal position and neutral alignment

2. According flowchart threading line instructions to begin threading.

3. Threading passes through the printing device - drying device - for color devices - embossing device - on the flower device - Origami device - Feed Roller - Folding wheel - the cardboard. (If you do not need to print without going through the printing and drying device)

4. If the production of printed products, please affix the printed roll resin version, if it is necessary for each color box 2 sets of flower resin version, according to the position of two aliquots paste board, you can use double-sided adhesive paste board. If the pattern is irregular, then the paste board needed. Recommend the use of conductive resin version better product, can improve print quality. Paste board after you install the ink cartridges, ink added plus, if the needs of a variety of colors chromatic position, loosen the chromatic color roll up sleeve according to the position to be adjusted.

5. Open drying, heated to 100 degrees Celsius, open the cutter motor test run, adjust the position of the printing and embossing, after adjustments can produce (shutdown, open the printing device, avoid prolonged contact with the resin version and stick paper )

三、 Equipment maintenance

In order to make the equipment work stable for long term, the equipment shall be regularly maintained, please make maintenance plan that fit your company according to following indication:

Examine screw regularly, and add machine oil for lubrication properly.

Regular examine fixing position of pulley on back driving to see it is loosen or not, examine synchronous belt is scuff or not due to prolapse of pulley. If it is scuff, it will cause synchronous belt broken.

Origami on the wheel fork and fork slots should be inspected regularly cleaned to prevent clogging causes fork because the fork groove deformation affecting production

Please keep each part on equipment clear, don’t put any tool or something others on the equipment.

When there is any abnormal noise during production, please stop the machine immediately and examine.

Faults | Fault Reason | Treatment |

Power supply input is normal,equipment operation don’t have response. | Emergency stop switch doesn’t return | Check equipment emergency stop switch and return |

Origami paper jam block can not be caught | 1.Tension spring is too loose or broken 2. Jam block fixing bolts loose | 1. Adjust or replace the tension spring 2. Re-mounting bolts and adjust the jam clearance |

Turn out on cardboard origami paper cutter position is very tight, not a very good introduction | The knife is not sharp enough | Please sharpening, if damaged, replace knife |

By continuing to use the site you agree to our privacy policy.