Copyright © 2025 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map

XY-GU-20A Automatic facial tissue machine

Training & operation instruction manual

Foreword

Thank you for purchasing and using our equipment! In order to make your use of this equipment safer and better, please read this User Manual carefully, it will help you understand the basic performance, structure, operation and maintenance methods of this machine, and help you how to use it safely and correctly Equipment to make it perform optimally, reduce failures and prolong service life. This equipment is made of steel-to-steel embossing, blanking, cutter roll cutting, interactive folding, slitting, counting and other processes. It has clear printing, the equipment uses automatic counting, and the whole row is output, which is convenient for packaging; it adopts spiral knife body cutting, vacuum suction and folding, high speed and stability; it adopts stepless speed adjustment to unwind, adapt to different tension of the original paper, and the original paper of each section It can be adjusted easily; use pneumatic paper feeding, pneumatic wide belt feeding, each roll of paper is equipped with an independent tension adjustment device, and the original paper is conveyed stably; the width of the product can be adjusted widely, and different types of original paper can be processed; at the same time, it can be selected according to customer requirements Steel-to-steel embossing, spraying, edging, gluing and other configurations.

1. Device parameters

Item | Parameters | Remark | |

1 | Main machine Power | Three-phase asynchronous 2.2kw | 2L |

2 | Three-phase asynchronous 3kw | 3L | |

3 | Three-phase asynchronous 4kw | 4L | |

4 | Three-phase asynchronous 5.5kw | 5L-14L | |

5 | Vacuum fan | 7.5kw-37kw | |

6 | Rear conveyor motor | 0.75kw | |

7 | Jumbo roll width | 350-2800mm | Customized |

8 | Finished product size | 175*175-240*240 | Customized |

9 | Jumbo roll inner core | 3inches | |

10 | Feeding method | Cylinder feed | |

11 | Embossing roll | Steel to steel | |

12 | Product speed | 60-100 M/min |

Note: The pumping machine can be customized with double-layer paper composite gluing and color printing according to customer needs.

2. Equipment operating instructions

2.1 Paper flow

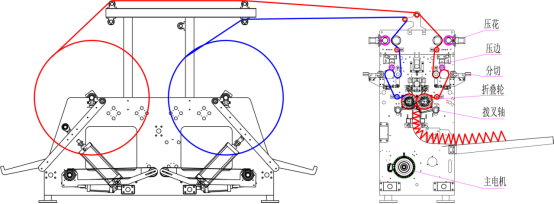

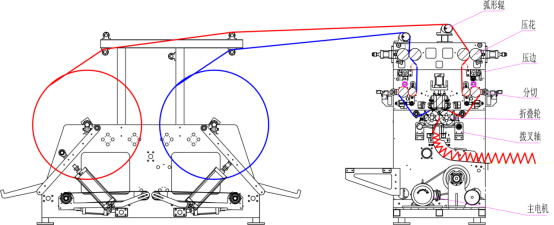

The paper passing process is as shown in the figure above. The lifting arm lifts the base paper to the specified position, and operates the jog button to draw paper as shown in the figure. (The embossing roller is separated when the paper is drawn, the felt cylinder is pressed, the breaking cylinder is in the initial position, and the manual valve is operated to make the rear conveyor contact the base paper.) The left and right folding rollers alternately fold into a hinged rectangular stack of paper, neatly arranged on the paperboard. Figure 1.1 shows the 2L-5L small shaft head paper-feeding process, and Figure 1.2 shows the 5L-10L large shaft head paper-feeding process.

2.2 Instructions

2.2.1 Centering the paper roll: Use the base paper to lift the manual valve and place the base paper in the position shown in the figure. Turn the base paper adjustment handle A to center the paper roll position and align the front and back paper rolls.。

2.2.2 Unwinding of the base paper: Use the base paper delivery manual valve to make the air cylinder push the belt holder up until the flat belt presses the paper roll. The linear speed of the flat belt may be controlled by the flywheel of the rear frame motor. (Note: It is strictly forbidden to operate the speed-adjusting handwheel while the equipment is running. Generally, no adjustment is required after the equipment has been debugged after leaving the factory).

2.2.3 Embossing roller: operation panel (front embossing, rear embossing), which makes the cylinder of the embossing roller act to compress and relax the embossing roller

2.2.4 Blank holder: operation panel (front blank holder, rear blank holder), using airbag to inflate or deflate, to press and relax the blank holder.

2.2.5 Vertical slitting (width positioning slitting): The operation panel (front slitting, rear slitting) is used to control the pressing of the front and rear knives. The width is adjusted by the cutter seat, and the pressure of each slitter is controlled by the corresponding pressure gauge.

charge and discharge edge embossing wheel airbag, press and hold edge embossing whee

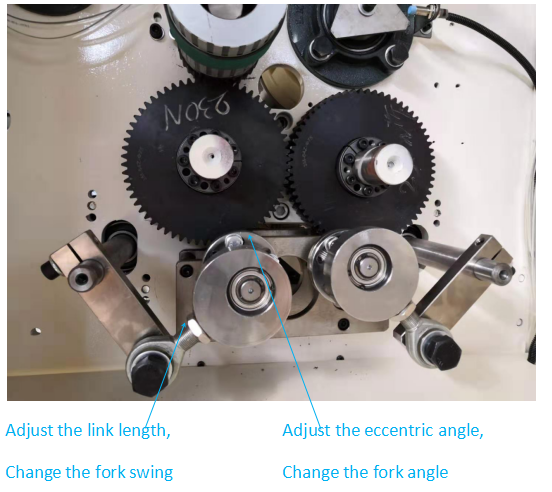

2.2.6 Folding molding: With the main motor running, the fork is driven by the eccentric link mechanism driven by the folding wheel. Once the folding molding is fixed, no adjustment is needed.

Note:The fork mechanism has been debugged before leaving the factory. Generally, no adjustment is required.

2.2.7 Counting and stacking: the control panel (drawing number). When the drawing number reaches a fixed value, the relay drives the cylinder to displace the paper output side plate, causing the finished product to be misaligned. The distance between the proximity switch and the induction wheel of the knife roller is 2mm to ensure that the display is normal.

2.2.8 Rear frame unwinding: The rear frame unwinding motor is controlled by the same frequency converter as the host machine. The speed adjustment handwheel of the rear frame motor can control the unwinding wire speed. It is strictly prohibited to operate the handwheel when the motor is running.

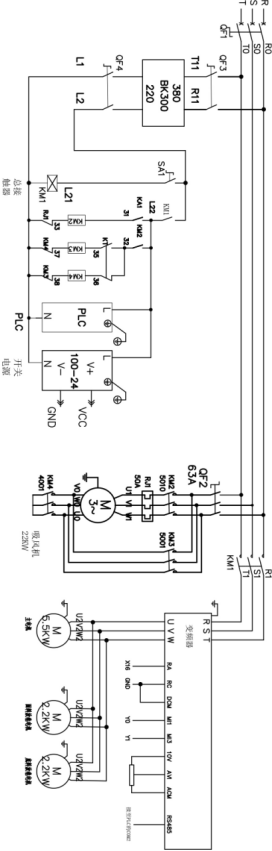

3. Electrical control

3.1 Pneumatic control

The air source of the paper towel machine is recommended to use no less than 3kw air compressor, and the stable supply of air source is required, and the air pressure is no less than 0.5MPa. The pressure feed cylinder and the base paper lift cylinder are controlled by two two-position manual rotary valves, respectively; the cutting cylinder, the blanket cylinder, and the cutting cylinder are controlled by panel buttons.

3.2 Operation panel

The input power of the paper towel machine adopts AC380V-50Hz, and the power supply voltage is required to be stable. Before turning on the machine, check whether the motor is turned correctly. First insert the electric door lock key to turn on the power, press the start button, and the alarm light prompts the device to run three times.

3.2.1 2-5L operation panel is a text window. The speed adjustment is operated by the panel speed adjustment knob. The upper inverter panel displays the running speed of the host. Shutdown operation: press the host to stop, the main motor stops, each cylinder returns to the initial position, turn off the power switch, and complete the shutdown operation. In case of emergency, press the emergency stop switch to stop the device. After troubleshooting, turn the emergency stop switch clockwise and restart the device as described above.

Operate the shift button, select the corresponding option, press ENT to confirm, EXC return, or operate the numeric button, and select the corresponding button.

3.2.2 5-14L pump with large shaft head, the speed adjustment is operated by the panel speed adjustment knob, and the touch screen panel displays the line speed of the host. Shutdown operation: press the host to stop, the main motor stops, each cylinder returns to the initial position, turn off the power switch, and complete the shutdown operation. In case of emergency, press the emergency stop switch to stop the device. After troubleshooting, turn the emergency stop switch clockwise and restart the device as described above. By operating the touch screen panel, you can set the number of stacking draws, the time of ink action, and the screen displays the current draws and the status of each solenoid valve.

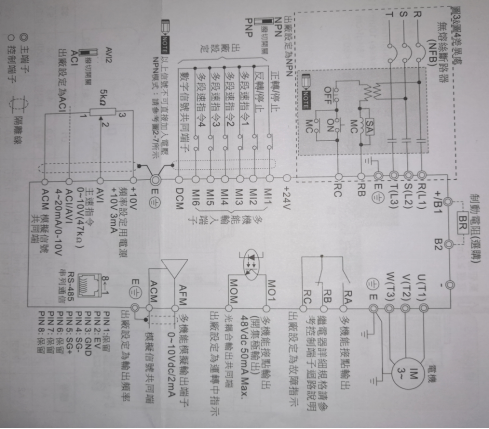

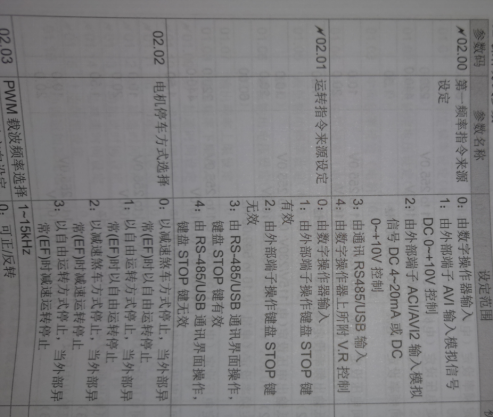

3.2.3 External circuit of inverter and common parameters

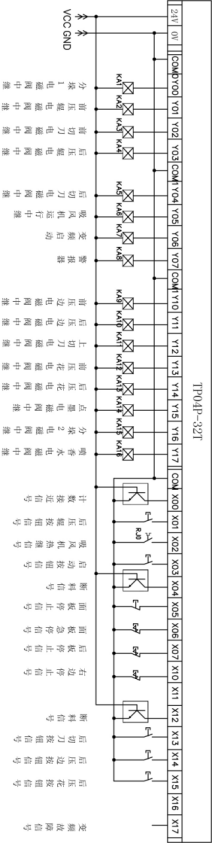

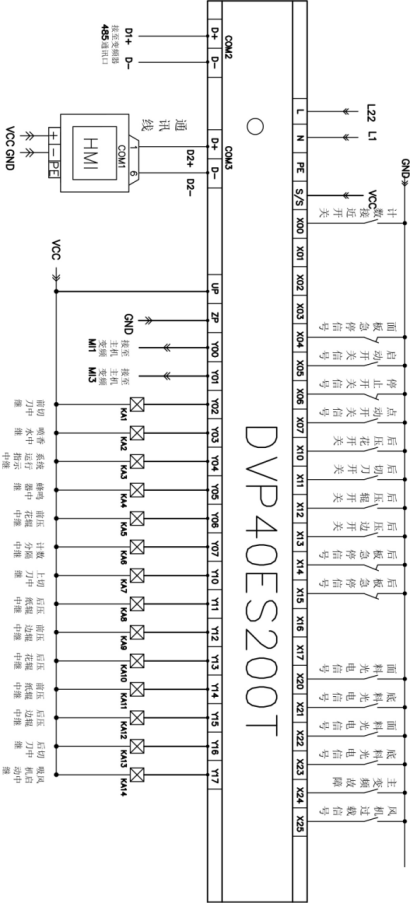

3.4 Text circuit diagram

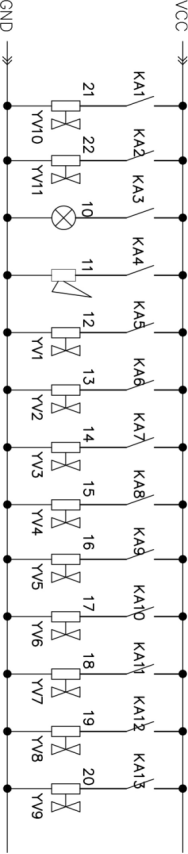

3.5 Touch screen circuit diagram

4. Precautions and maintenance

Be sure to turn off the power when wiring the circuit and repairing the equipment.

When the external power supply is abnormal and the equipment fails, in order to make the entire equipment operate safely, be sure to install a safety circuit device outside the electrical equipment. Incorrect operation may cause accidents.

Never modify the internal circuits and components of the device by yourself

Before starting, you must ensure that there is no interference in the actions of each actuator

Compressed air source must ensure that there is more than 3Kgf

When turning off the device, you must turn off the power by the control panel before you can cut off the power.

Please guide the paper while it is stopped. Part of the process uses the jog paper guide function to guide the paper. Do not put your hand into the roller.

It is strictly forbidden to bring any part of the body close to or touch the moving parts during the operation of the device. Before turning on the device, please close the safety cover of the device. During the operation of the machine, it is strictly forbidden to place any part of the body near or touching the moving parts. Failure to do so may cause serious personal injury

The air storage tank should be drained regularly and checked for leaks in the pneumatic circuit.

It is strictly forbidden to change the parameter setting value randomly and frequently

The parameters of the inverter on the device have been strictly tested before leaving the factory. Do not change these values randomly or frequently, otherwise unpredictable accidents may occur. If it is necessary to adjust the set parameters, please follow the steps in this manual to set and adjust.

Any unauthorized modification of any part of the equipment is strictly prohibited

Unauthorized changes to the equipment may cause unpredictable accidents. Do not modify the equipment without prior consent of the company, otherwise all personal injury and material damage caused by it will be the responsibility of the changer.

By continuing to use the site you agree to our privacy policy.