Copyright © 2025 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map

This production line consists of non stop rewinding machine, automatic log accumulator machine,automatic log saw machine and bundle packing machine. From the jumbo roll into the finished rolls, the whole line work smoothly and run stable, saving the labor cost and reducing the labor strength. It’s best choice for the producing hygienic paper products.

Non stop automatic glue lamination toilet paper machine production line

XY-TQ-A

Technical performance characteristic:

This production line consists of non stop rewinding machine, automatic log accumulator machine,automatic log saw machine and bundle packing machine. From the jumbo roll into the finished rolls, the whole line work smoothly and run stable, saving the labor cost and reducing the labor strength.It’s best choice for the producing hygienic paper products.

Our service

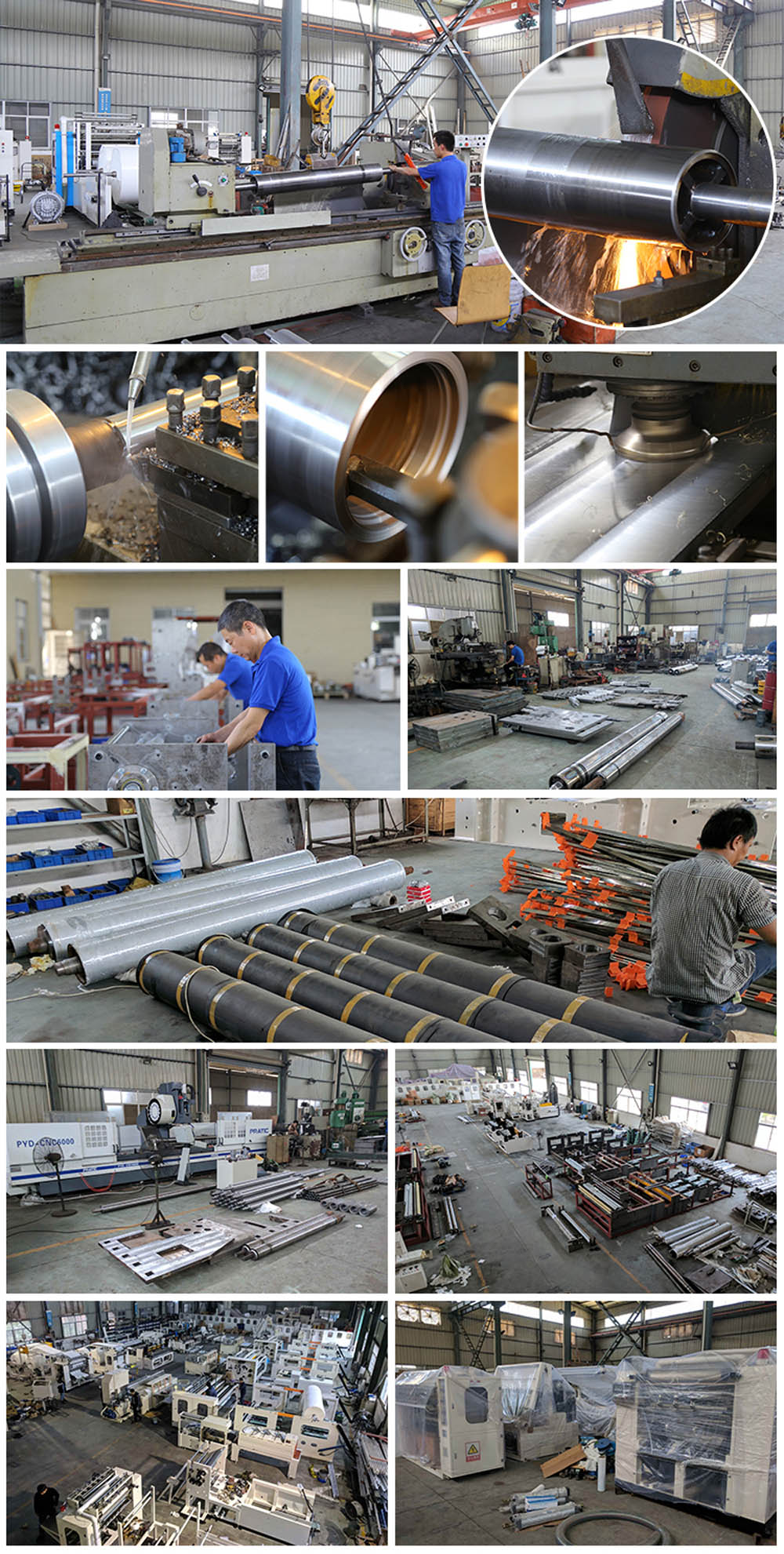

Workshop

Our company

Professional supplier of:

1) Toilet Paper Machine (1.2m--2.8m width of parent roll, Customize Service)

2) Roll Kitchen Paper Towel Machine (1.2m--2.8m width of parent roll, Customize Service)

3) Facial Tissue Machine (2-8 output lanes)

4 )Napkin Paper machine(L-fold, 1/4-fold, 1/6-fold, 1/8-fold and other multi-fold type)

5) Hand Towel Paper Machine(C-fold, V-fold and N/Z fold type)

6) Pocket Tissue Machine(mini and standard size)

7) All kinds of Tissue Paper Cutting and Packing Machine

8) Another Household Paper Equipments and Production Line.

Welcome to contact us to get more details !

We can design the machine according to your request.

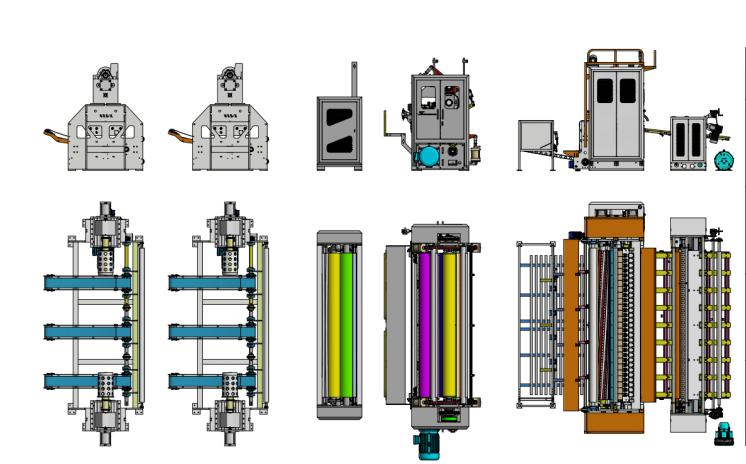

The high-speed cored rewinding production line is composed of a large paper unwinding rack, an adhesive bonding and embossing unit (optional), a high-speed continuous rewinding main unit, an adhesive (or non-adhesive) sealing machine, a large storage rack, a high-speed dual-channel large rotary paper cutter, a high-speed core winding machine, a paper core storage rack (optional), and automatic packaging machines of various specifications and packaging forms. All functional units and components work seamlessly together, ensuring smooth operation, making it an ideal piece of equipment for producing toilet paper and colored kitchen paper.

The rewinding main unit uses a servo motor to drive the riding roller for accelerated paper cutting. The entire electrical system employs a precise Omron eight-axis motion control system, a Kunlun Tongtai large-screen human-machine interface, and a one-button language switching display for Chinese and English. Each functional component uses a variable frequency motor or servo motor for independent synchronous drive. It can accurately detect the position of the perforation dotted line and complete the paper cutting action through the servo motor, achieving clean, neat, and stable edge cutting. Incorporating internationally advanced technologies such as mechatronics and optoelectronics integration control, it achieves a high degree of automation and user-friendliness.

| Speed | 200 m/min |

| Base paper basis weight | 14g/m²-42g/m² |

Maximum diameter of raw paper | Φ2500mm |

Maximum width of raw paper | 2850mm |

| Finished rewinding diameter | φ90-φ140mm |

| Perforating ratio of the dotted line | 3mm:1mm; other specifications can be specified. |

| Power supply | Standard three-phase 380V 50Hz (special specifications can be specified) |

| Air supply | 0.5Mpa or higher |

Machine Model | XY-203 Log Accumulator |

Log Width | 1750~2800mm(Other size can be specified) |

Log Diameter | Φ95mm~Φ140mm |

Log Standings | 150-160Logs |

Accumulate speed | 20 logs/min |

Log Qty | 200 logs(need to be ordered) |

Overall Dimensions | 4000*3000*5500mm |

Programming Controller | PLC(Delta) |

Technical performance characteristic:

XY-AI-280 Double Channel Log Saw Machine is used for cutting the toilet paper roller and kitchen towel paper roller, it’s with high automation and efficient. Adopts advanced servo driving system, frequency conversion speed regulating, PLC control and touching screen operation.

| Speed | 160-200 rolls/min |

| Toilet log length | ≦2850mm(it can be made according to customer request) |

| Finiahsed toilet roll diameter | 90-120 mm |

| Finiahsed toilet roll width | ≦300mm |

| Power | 11Kw 380V 50Hz three phase |

| Cutting blade | φ610*4.7mm |

| Overall size | 6500*2500*2000mm |

| Weight | 4500 kg |

Production speed | 90 m/min (raw paper speed, not tube exit speed) |

| Number of paper layers | 2-4 layers |

| Raw paper weight | 180-350 gsm |

| Bottom paper lubrication | Roller cloth, automatic oil dripping |

| Glue heating device | Heating tube 500W*2 |

| Paper core inner diameter: | Φ40mm-Φ76mm (specification required) |

Cutting device | Circular blade, pneumatic slitting |

Length control | Photoelectric sensor control, length error ±3mm |

| Raw paper pressure control | Spring pressure plate structure, pressure manually adjustable |

By continuing to use the site you agree to our privacy policy.