Copyright © 2025 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map

The production line is consisted of automatic transferring napkin tissue making machine and automatic napkin tissue packing machine. High productivity and labor saving

Automatic transferring serviette tissue machinery production line XY-OQ-7000

The production line is consisted of automatic transferring napkin tissue making machine and automatic napkin tissue packing machine

Main feature:

1. Adopt flexible printing unit, high procession ceramic anilox roller, making the water ink equally spread and print out extract and stereo pattern.

2. Raw material through synchronous belt and come into calendaring unit, and into embossing unit. There is tension unit between raw material and calendaring, raw material and embossment.

3. Folding wheel automatic stop machine protection unit.

4. Automatic rectify system.

5. Automatic constant temperature drying system.

6. Raw material broken protection unit. Automatic speed down unit when raw material run out. Folding roller stop protection unit.

7. Water ink circulation system.

8. Full-automatic unreel control system: track the speed of main machine by computer, transmit to servo system, the servo system convey paper to printing system accurately according to the order of computer and make perfect product.

Main Technical Parameters:

| Speed | 1000 sheets/min |

| Folding type | 1/2,1/4,1/6 and 1/8 |

| The width of jumbo roll | 200-400 mm |

| The diameter of jumbo roll | 1200 mm |

Jumbo Roll Material Qualify | 1-2 layers, 18-25g/m2. |

Controlling System | PLC control |

Way of printing | Flexo printing. |

Material of printing | Water-solubility ink |

XY-BT-298 Automatic tissue paper packing machine

Main performance and structure features:

1. Adopt packing method by wrapping, hemming and sealing with compact structure and high product appeal.

2. Adopt the controlling system of step-less frequency conversion, touching screen and PLC, clear display and easy maintenance.

3. Adopt auto-putting conveyor, easy to be connected with automatic production line, saving laboring cost.

4. Stepless-speed regulation with double transducer, automatically adjusting packing film length.

5. High autoimmunization, high specialization, high efficiency and but less trouble.

6. Different sizes can be handled easily thanks to a fast and simple changeover facility.

| Speed | 30-100 bags/min |

| Packing size | 100-230*90-200*40-160 mm |

| Packing film | CPP,PE,OPP/CPP,PT/PE and other film sealed on both sides |

| Power | 19Kw 380V 50Hz three phase |

| Overall size | 3560*5885*1925 mm |

| Weight | 3000 kg |

Our service

Packing & Delivery

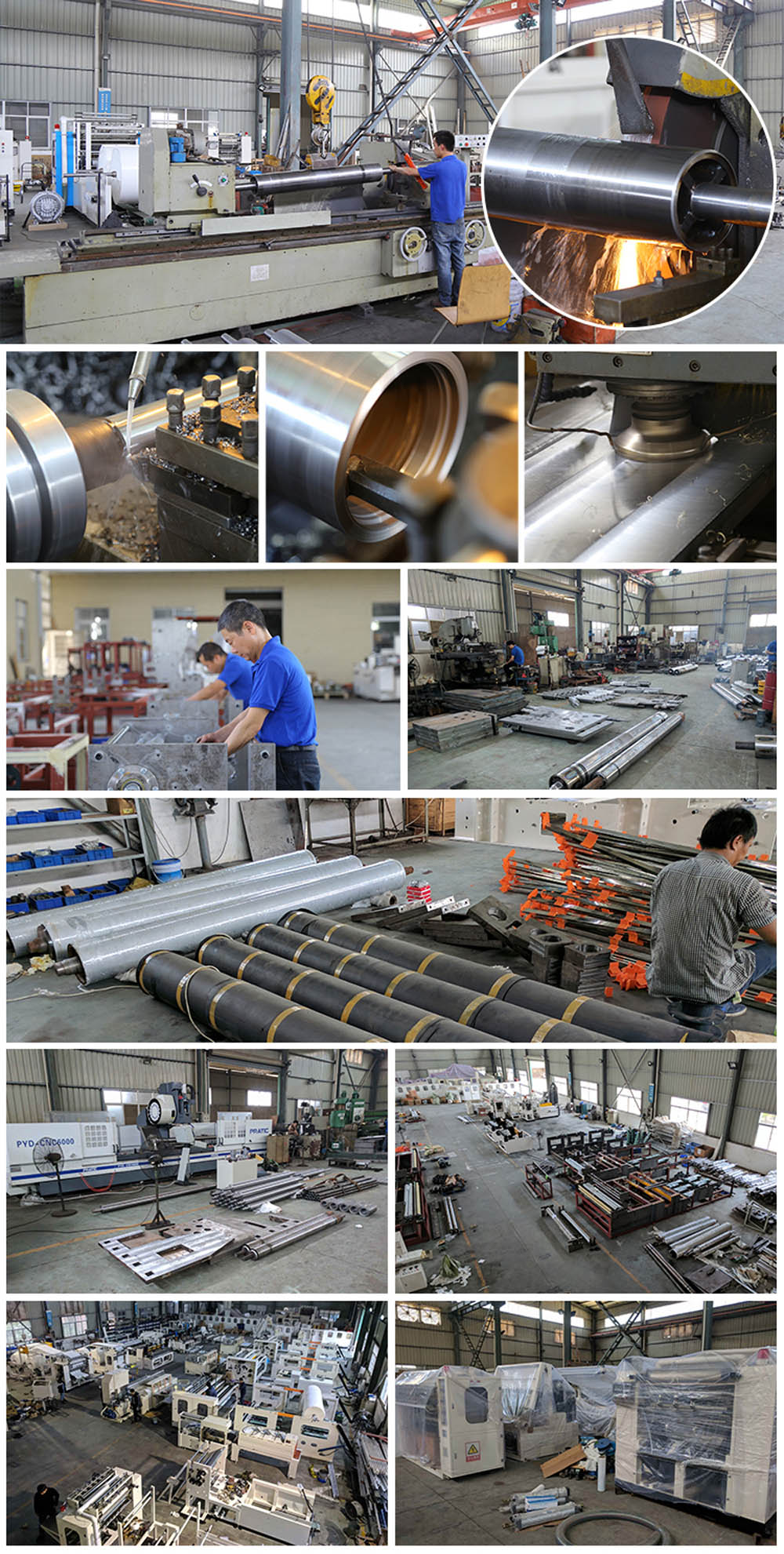

Workshop

Our company

Professional supplier of:

1) Toilet Paper Machine (1.2m--2.8m width of parent roll, Customize Service)

2) Roll Kitchen Paper Towel Machine (1.2m--2.8m width of parent roll, Customize Service)

3) Facial Tissue Machine (2-8 output lanes)

4 )Napkin Paper machine(L-fold, 1/4-fold, 1/6-fold, 1/8-fold and other multi-fold type)

5) Hand Towel Paper Machine(C-fold, V-fold and N/Z fold type)

6) Pocket Tissue Machine(mini and standard size)

7) All kinds of Tissue Paper Cutting and Packing Machine

8) Another Household Paper Equipments and Production Line.

Welcome to contact us to get more details !

We can design the machine according to your request.

By continuing to use the site you agree to our privacy policy.