Copyright © 2025 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map

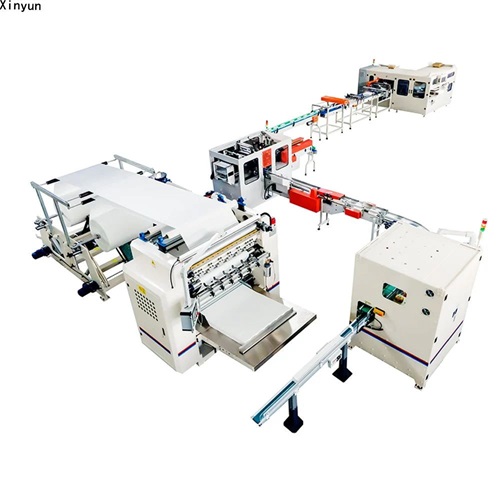

Toilet rolls are used inside a toilet, while napkins are used for general cleaning. Using facial tissue is essential when you want to use tissue paper on your face for cleaning or drying. These rolls are made with a Facial Tissue Machine; here is everything you need to know about how it works.

There are 7 steps involved in producing facial tissues on a facial tissue machine. Below are the details of each of the steps.

The facial tissue machine gets its raw material and starts by cutting it into the desired pieces. The cutting is automated, using high-quality blades to ensure less wastage and perfect cutting results every time. As the machine is automated, you just need to give the desired size, any other instructions, and the raw materials for the machine to start working.

A huge part of the quality in the facial tissue industry comes from embossing patterns on it. It makes the tissue feel puffier, so it stays soft when rubbing against the skin. So, after cutting the tissue, it is moved to the embossing section, where you can get your desired pattern embossed on it.

One last step crucial in the manufacturing process is vacuum adsorption folding. This part folds the paper into a V shape which is essential for efficient use when packed. While the tissue goes through this process, it is ensured to get the least contaminants on the tissue and use auxiliary manipulator folding technique for better efficiency.

After folding comes the counting part, and in the counting part, the machine automatically counts and stacks the tissues as they move out of it. This part also stacks the correct number of tissues as specified by the operator. So, you can set it to create stacks of 100 tissues each, and the machine will automatically do it.

The machine keeps stacking tissues on one end, and on the other end, the complete stacks keep moving on the conveyer belt for the next phases of the manufacturing process, which include packing and sealing.

The facial tissue must be cleaned and sealed in vacuum-sealed packs until it reaches the customer. The sealing machines are usually designed with tension adjustment features so the sealing intensity can be set according to the user's requirements.

Lastly, the sealed packets move to the packing stage. It is usually semi-automatic, but some machines can automatically pack the packs into boxes. This step involves taking multiple packs and putting them inside boxes, making them ready to ship safely.

A Facial Tissue Machine may look and function like other tissue machines like napkin and toilet roil manufacturing. However, extra steps in the procedure, like folding, make the final product perfect for use on your face. Start your facial tissue business today and learn which machine best suits your requirements. Contact our experts now.

By continuing to use the site you agree to our privacy policy.