Copyright © 2020 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map Powered by iwonder.cn

Model No. XY-GU-27

Semi Automatic Napkin Tissue Packing Machine

How to use:

5changing the packaging specifications of the adjustment

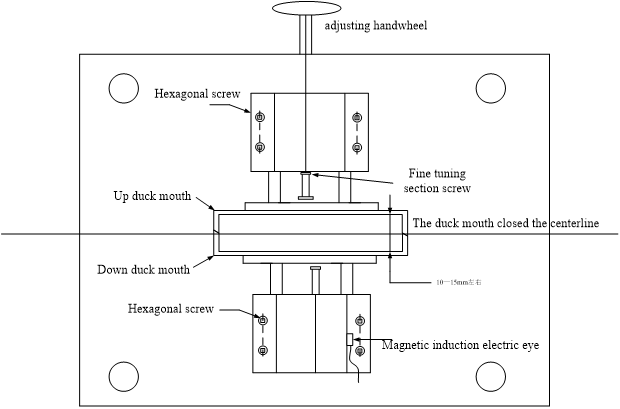

the duck mouth framework map

1 the adjustment of the discharging mouth:

Because of the thickness of the product packaging specifications different, need to adjust pressure board, (discharging) and hold the height of the bag and seal pressing for examople. For example: if you want change 200 papers(80 mm thickness) into 160 papers( 60 mm thickness), the method is as follows:

1. the first step: shut down the machine power and air to ensure that the machine power to snuff out before they can adjust the machine to pay attention to safety.

2. the second step: please unscrew connecting two discharging mouth cylinder (32 x50 biaxial cylinder) on the adjusting screw (m8 outside hexagonal screw) cylinder to about 25 mm can travel adjustment, if put the paper thickness change from 60 mm to 80 mm is transferred to the 35 mm or so. Adjustment method: put the m8 outside hexagonal screw counterclockwise twist tighten nut fixed after adjust well. If discharging mouth broken bags please unscrew the four socket head cap screw and counterclockwise around the cylinder screw dynamic adjust the discharging mouth micro adjustment can make the bag hold tight and not be broken and then fasten the hexagonal wire the handwheel.

3. the discharging mouth to adjust the height of the counting methods: with the highly minus the discharging mouth of the bag when closing the size of 2 cm (20 mm), for example: the bag height 65 mm minus discharging mouth 20 mm is 45 mm (65-20 = 45 mm)/with 45 mm, divided by two cylinder to go trip is equal to 22.5 mm (45 members present 2 = 22.5 mm)/with 80 mm minus the discharging mouth cylinder total trip to go trip 22.5, which is discharging mouth cylinder stroke location number (80-22.5 = 57.5) after discharging mouth size adjusted the tightness of the sack front-rear mouth first to see if any slack phenomenon of monotone on discharging mouth at the top of the handwheel to looseness suits.

4. after adjusting the thickness of the discharging mouth, need to adjust the discharging mouth magic eye (magnetic induction electric eye) on the cylinder, the discharging mouth cylinder must be according to the lowest position, open the power supply to loosen magic eye screw, move up and down the magic eye that position on the cylinder, and then locked magic eye in there.

Note: if you have magic eye cylinder in the cylinder to work must be in a state of bright to next step.

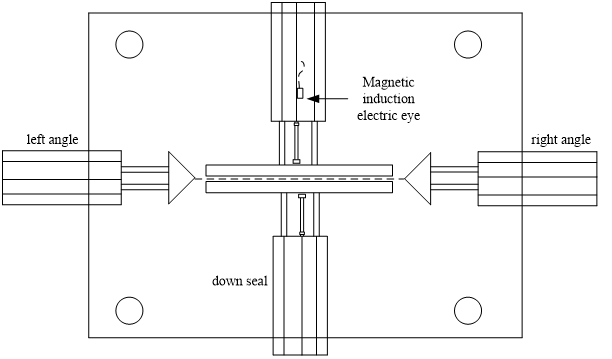

(2) the angle of the sealing mechanism schematic diagram

2 angle and sealing to adjust:

1. adjust the angle of the height of the cylinder: first turned on cylinder and around under the four m8 hex socket screws and then adjust the height of an interpolation angle in the seal cylinder centerline coincides with the duck mouth cylinder, then tighten the four m8 socket head cap screw.

2. the angle of the flat plug is inserted in the two sides of the position to be in the middle of the discharging mouth closed space-time bit. Note: the flat plug location than the location of the triangle plug is beyond more than 5 mm.

3. pressure board: the regulation of cardboard at the bottom than at the bottom of the discharging mouth position less than 2 mm, 3 mm left and right sides.

4. after the above steps to adjust try in the product packaging effect whether meet the requirements, then can be put into production.

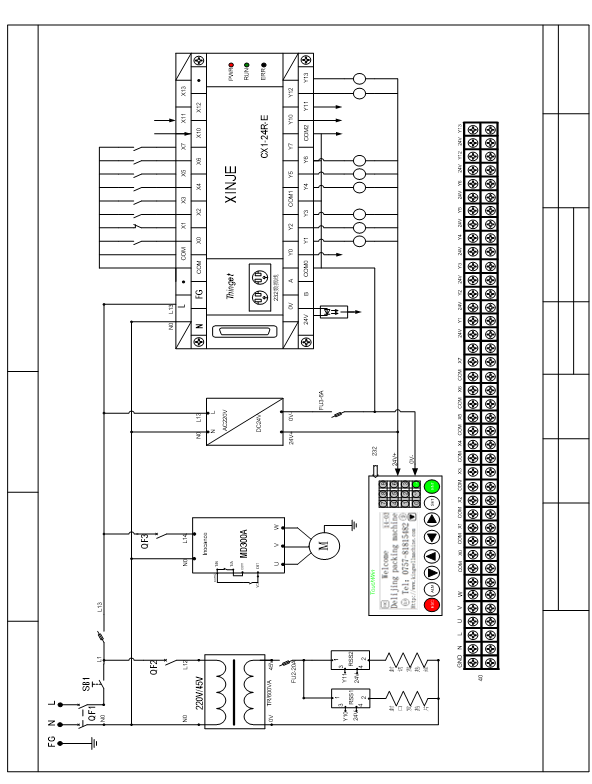

Under normal circumstances "boot" programmable controller plc input signal x: x1 Emergency Stop.

X6 : the push paper cylinder in home position.

Y0: the conveyor start running signal.

If no signal, then machine can’t work, pls adjust the electric eye to to right position.

Adjust the magnetic induction switch to the right status.

The fault code:

1) (Y6-X2) Y6 alarm information opening cylinder did not open, X2 opening dynamic magnetic sensor is not detected.

(2) the X3 (Y3-X3) Y3 press paper cylinder without the pressure, the pressure of the paper is not detected by the magnetic sensor.

(3) alarm information (Y4-X4) Y4 pushed the paper cylinder is not introduced, the X4 push paper move a magnetic sensor not detected.

(4) X5 (Y5-X5) Y5 sealing cylinder sealing, and the sealing of the magnetic sensor is not detected.

(5) (Y7-X6) Y is not in situ, and the X6 is not detected in situ magnetic sensors.

(6) Y7 (Y7-X7) is not stretched out into the cylinder, and the X7 is not detected in the feed.

(7) X11 (Y4-X11) Y4 push paper cylinder did not return, the paper in situ magnetic sensor is not detected.

The machine setting parameters initialization function, the user is in use process if the parameter correction method of chaos and can use this feature when back to all of its parameters to restore the factory values. Method is as follows:

Press E-stop button and step the foot switch and press 9 seconds.